Why Ice Block Maker is not Working? Troubleshoot the Issues

Our guide will answer the question on why the ice block maker is not working and provide ice block maker troubleshooting steps to get it up and running again. Whether you are having problems with ice production or maintenance issues, this article will help identify common problems and their solutions.

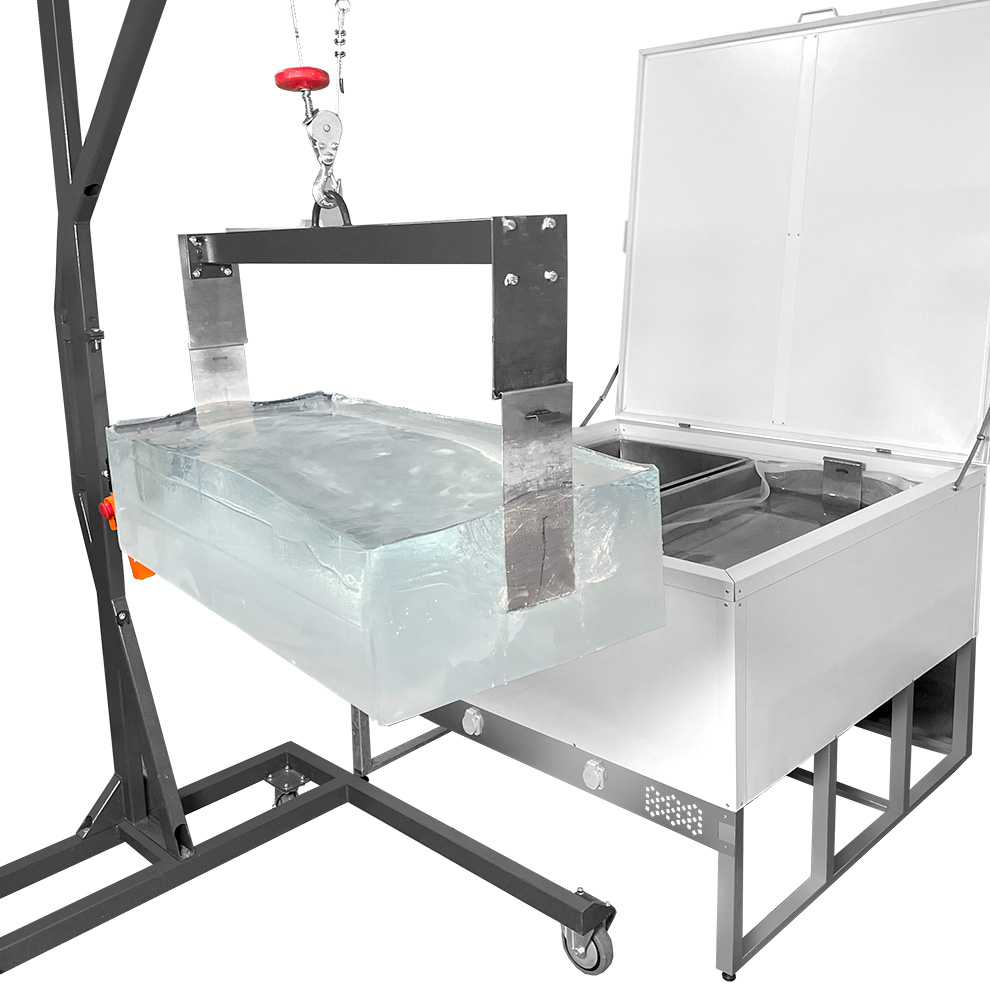

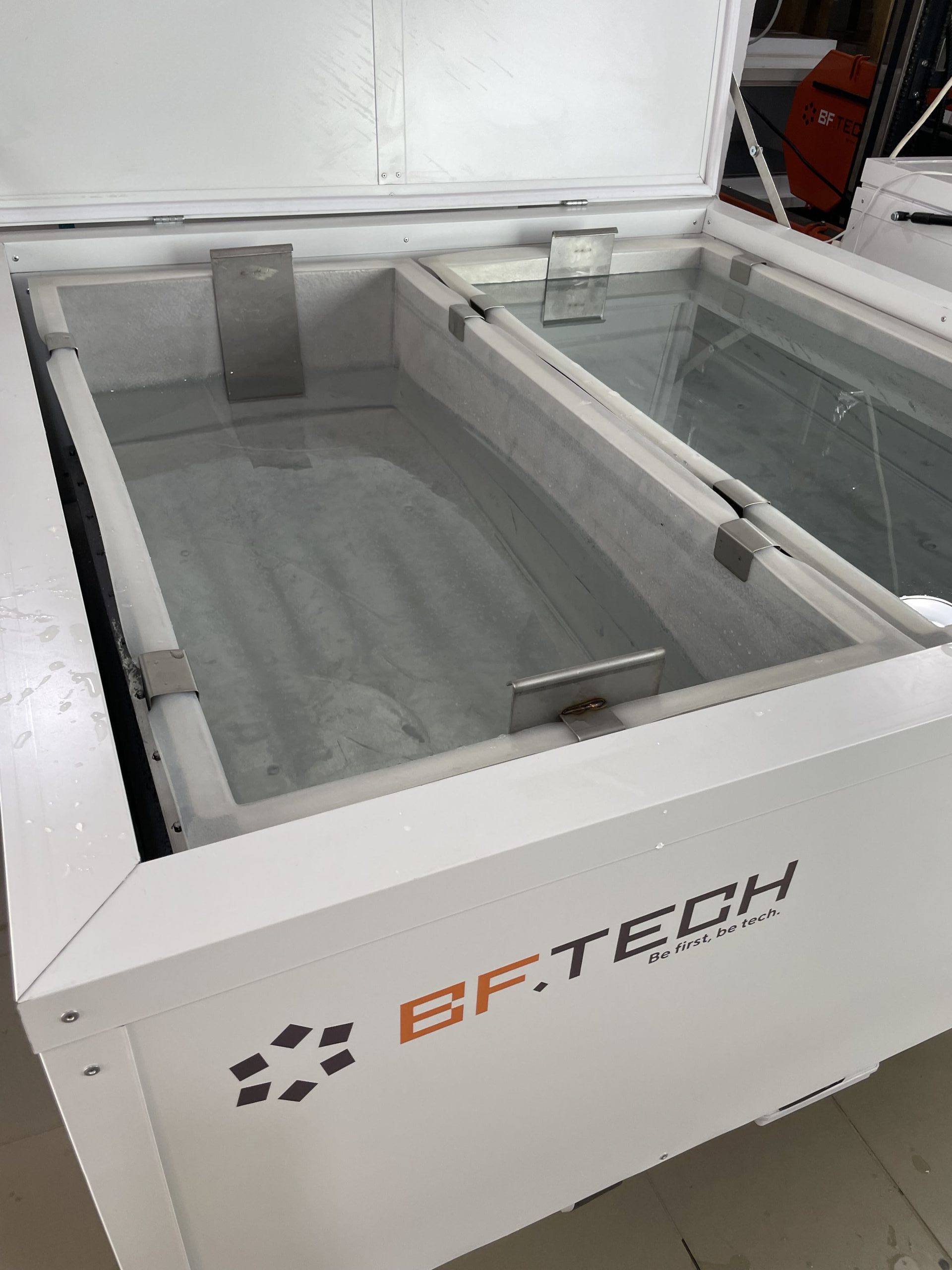

We will also cover a few models from BFTech: P300, P150, and P30; which include some separate troubleshooting steps specific to each model. For general information about a block ice making machine, visit BFTech’s main page.

4 Common Problems with Ice Block Makers and Troubleshooting Steps

When it comes to ice block maker machine repair, there are certain things that can go wrong that we need to know when fixing them.

Here we have listed four of the most common ice maker issues that could be the cause of why your ice block maker is not working properly as well as what needs to be done in order for this problem or issue to be resolved successfully.

1. Ice Maker Not Producing Ice

One of the commonly made complaints about an ice block maker is that it does not produce any ice at all when switched on, which is actually its very basic function. There can be many reasons for this ranging from water supply and water fill tube problems, temperature missettings, and mechanical failures within itself, among others.

Cause:

The causes of low or no production could be lack/little water flow into the machine due to clogging somewhere along the pipes, water leak, or incorrect freezer settings, such as too high freezing point so that no melting occurs, thereby preventing the formation of cubes through the solidification process.

Fixing Steps for Ice Maker Not Producing Ice

Step 1: Check Water Supply

Ensure that the water supply to your ice block maker is turned on and that the hose is not kinked or blocked. One of the common ice maker problems could be a clogged water filter, which needs to be replaced or cleaned.

Make sure that there is enough water flowing into your device by turning on the tap fully then see whether the hose connected between the faucet and the back side of the fridge where this appliance is located has any kinks or blockages. If yes, unblock or replace them. Another common issue might involve clogged filters which should be cleaned regularly or replaced depending on the type used.

Step 2: Inspect Freezer Temperature

In case temperature settings are incorrect, adjust them accordingly since they may not be favorable for the production of ice cubes. The best level should range between 0°F and 5°F; anything above that will cause failure in making ice blocks, so try keeping within the range mentioned above.

Step 3: Reset the Ice Maker

Sometimes, just resetting can fix everything because there might have been a slight power surge or something similar during the operation. So, disconnect it from the electricity for a few minutes before reconnecting and see what happens afterward. Specific models have their own reset instructions that should be followed, especially those designed with electronic controls like our P30 model.

2. Ice Blocks Melting Too Quickly

When ice blocks melt too quickly it shows that your professional ice block maker is not efficient enough. This problem may result from wrong insulation or environmental conditions around the device.

Cause:

Fast melting usually occurs when machines are installed in unsuitable areas where there is too much heat energy being supplied into the system. Thus causing rapid changes within various components such as coils meant to produce the coldness needed to freeze water droplets into solid state form.

3. Tips to Address Ice Blocks Melting Too Quickly

Step 1: Check Installation Area

Ensure proper placement of your ice machine away from direct sunlight exposure as well as in places with high temperatures (like next to ovens).

Step 2: Improve Insulation

Examine the insulation around your ice-making unit, as poor insulation can cause higher internal temperatures. You may also need to add more insulation.

Unusual Noises During Operation

Weird noises during operation may indicate that there are some internal mechanical problems that need to be urgently repaired by a specialist.

Cause:

The source of the noise in question could come from many places such as the motor or evaporator due to loose parts or mechanical wear and tear.

4. Resolving Unusual Noises During Operation

Step 1: Identify the Noise Source

Listen closely to find out if it’s coming from the motor, evaporator, or other components. Different sounds indicate different issues.

Step 2: Tighten Loose Parts

Rattling sounds might be caused by loose screws and panels. Fasten any loose parts together tightly before checking for any further noise production issues.

Ice Block Maker Overflows

An overflowing refrigerator ice maker machine can create a mess and point out problems with the water input system like overactive water inlet valves or faulty water level controls.

Cause:

This happens when there is something wrong with either one of these two: water inlet valve malfunctioning or wrongly set up settings on water level control, which leads to overfilling of machines.

Preventing Ice Block Maker Overflows

Step 1: Adjust Water Levels

Check the sensor responsible for detecting when enough water has been filled then adjust accordingly so that it does not exceed its capacity again, thus preventing overflowage from happening.

Step 2: Inspect Water Inlet Valve

You should inspect whether this component works properly because sometimes it may become faulty or get stuck open causing more than required amount of flow rate which results in too much water being let in at once. Replace it with a new one if it is defective.

Conclusion

In this manual, we have covered some common reasons why your ice block maker isn’t working and provided ice block maker troubleshooting solutions. Whether it’s a lack of production or overflowing of machines, knowing what causes these problems and taking appropriate measures can revive the functionality of your device.

Frequently servicing the equipment along with timely professional ice block maker machine repair work greatly increases its lifespan as well as ensuring that it maintains consistent efficiency levels throughout use. Always consult the user guide for precise instructions concerning care procedures and seek expert assistance where there is doubt about the personal capability to undertake repairs or if faults persist.

FAQ

My professional ice block maker is not working suddenly, what should I do?

Several reasons could cause why your professional ice block maker is not working. For example, a blocked water filter, not enough flow of water, electrical malfunctions, or incorrectly set freezer temperature. First, make sure there is no interruption in the water supply and check if the filter needs to be changed. Also, ensure that all electrical connections are secure and that the thermostat is set correctly. Regular preventive maintenance can prevent such sudden interruptions.

What are the steps to reset an ice block maker?

Temporary malfunctions can often be fixed by resetting your ice maker. To do this, first, turn off the ice maker and disconnect it from its power source for a few minutes before plugging it back in. When the system restarts after doing so any errors should be cleared and normal operation resumed. Consult your owner’s manual for specific reset instructions applicable to your model, which may involve pressing certain buttons in sequence.

How can I tell if my ice maker’s water line is blocked?

If an ice machine starts producing less or no ice at all, it may be due to a blocked water line. Look out for kinking or blockage signs in visible parts of the water line such as bends where pipes come together or near valves. Reduced flow when using the dispenser could also mean a clog somewhere along the supply tube. It is advisable to replace filters regularly according to the manufacturer's instructions so as not only to avoid getting plugged up but also to ensure smooth running.

Why might my ice machine produce less ice than it is supposed to?

This can be caused by dirty condenser coils which restrict airflow across them, thus reducing their efficiency, and in environments with low ambient temperatures outside, or faulty evaporator coils where there could have been some damage done either mechanically or through freezing over time. Clean out any dust accumulated on these coils using appropriate tools like brush vacuums while taking care not to damage delicate fins. Also, check if anything has been placed on top of the machine that could be blocking air flow through vents.

What causes small or oddly shaped ice cubes in an ice block maker?

This is usually a sign of low water supply to the ice maker. The most common reason for this problem is clogged filters or low pressure. You should check if your water pressure meets the minimum requirements set by manufacturers and replace filters as necessary. Also, make sure there aren’t any alignment issues between the fill cup and mold where they touch each other because misalignment can cause such abnormalities.

What leads to oversized ice cubes in my ice maker?

If you find that ice cubes are bigger than expected then it’s possible that there might be an issue with how much water flows into the mold at once. Check whether there are any leaks around the inlet valve which may cause overfilling and adjust the amount of water entering the system according to the manual instructions provided.

What are common reasons for an ice maker to leak water?

Water leakage can occur when certain parts, like ice trays, become cracked or improperly seated, connections get loose at inlet valves, etc. Another possible cause could be a damaged hose during the installation process. Always ensure all components have been fitted securely without cracks visible on surfaces so as not only to prevent but also to maintain efficiency levels for longer durations.