How Does an Ice Ball Press Work?

Ice balls seem to be all the rage across bars, restaurants, and even home parties. They look stunning and add a touch of style to the drinks you serve. And not only that — due to their spherical shape, ice balls melt way slower than the traditional ice cubes, preventing the drink from getting watery too early but still effectively cooling it down.

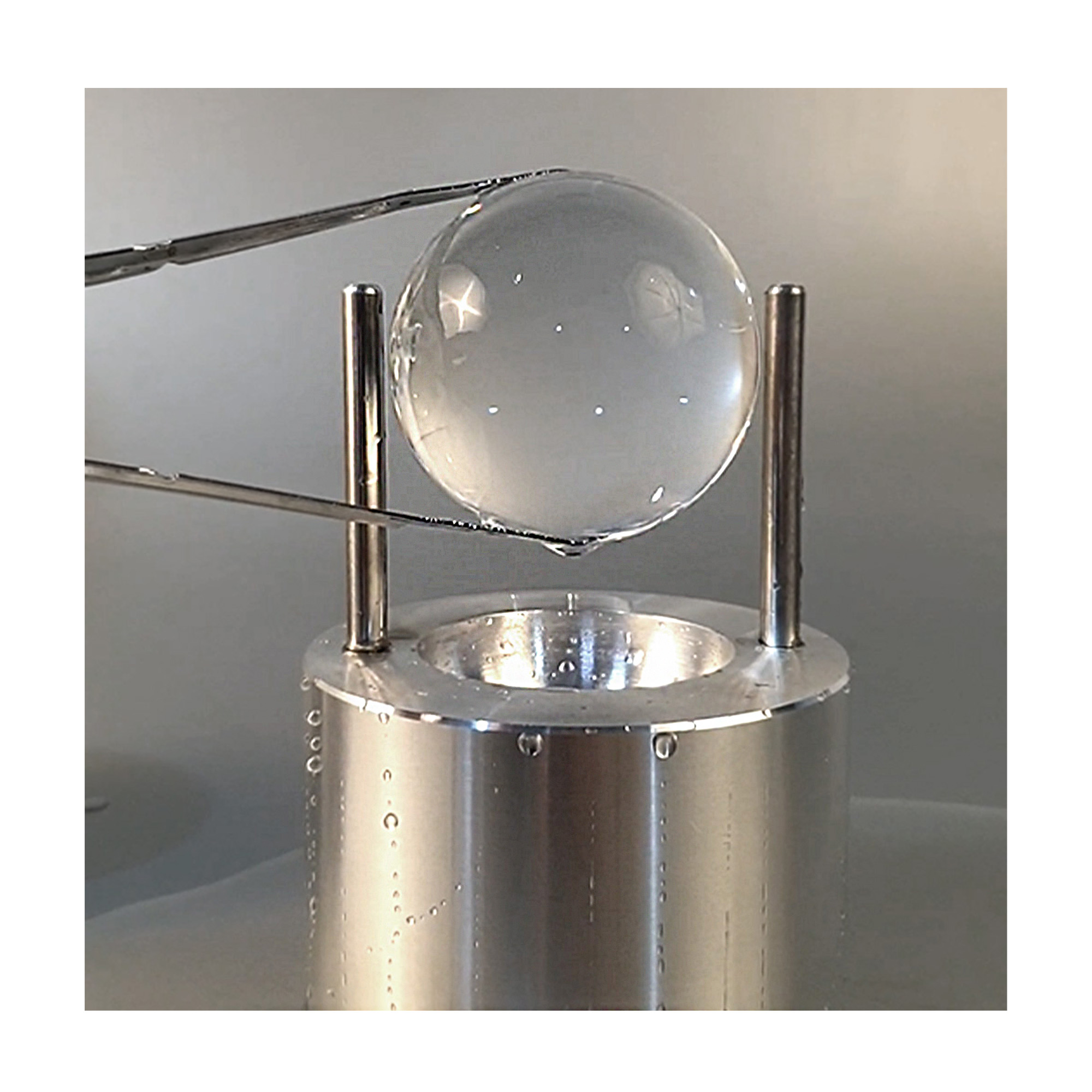

Of course, making a perfect ice ball is impossible without an ice ball press. This machine can quickly make ideal ice spheres. Pure magic, don’t you find? However, an ideal ice ball sphere is more about physics. So how does an ice ball press work? Let’s see!

Comparison of the Ice Balls Presses

An ice ball press consists of two large metal blocks, each with a hemisphere carved into a side, which create a sphere together. The metal blocks are joined with two vertical shafts. After you place a block of ice into the press between the shafts, the top of the press slides down, melting and carving the ice into a spherical shape. As already mentioned, the whole process relies on physics, and, to be more precise, on conduction and gravity.

Conduction

Thermal conduction is the key principle in ice ball machines. No matter their material and size, all ice ball presses use thermal conduction to create ice balls. How do ice ball makers work? To put it simply, the metal is warm and the ice is cold, and when they touch, the ice press metal gets colder and the ice gets warmer. The greater the difference in temperature, the quicker the process.

Gravity

Next comes gravity — another essential feature of any ice press. Gravity is responsible for the force that “carves” the ice into a sphere. This explains why ice ball machines are so heavy. The weightier the press, the faster it works.

How Does an Ice Ball Press Work: a User’s Perspective

Now you know how does ice ball press work, but how to actually use it? That’s a breeze!

- Get a block of ice out of an ice block mold.

- If needed, cut it to a size to fit in the ice press. It’s best when the square spills over the sides of the ice press sphere shape mold — it will ensure that ice melts into the correct shape.

- Put the ice into the press and place the top section of the device on.

- Add the ice to the drink. A quick tip: a bourbon glass with an hourglass shape or a rocks glass are best to prevent the ice ball from rolling into lips.

How To Choose an Ice Press

We hope you’re satisfied with our detailed answer to the question How do ice ball presses work?, and we guess you might be wondering how to choose the right machine to create perfect ice spheres. Ice ball presses may come in different sizes, designs, and materials.

Design

All ice ball presses look similar, however, there are several features that make them different in design. Some machines have handles, however, they don’t affect the quality of ice balls — they’re just a bit more convenient to use.

Also, ice presses vary in the way the water is vented out. In some machines, the vent comes out the side, while in other versions have vents that shoot down via the central axis of the sphere.

Material

The two most widespread materials for ice ball presses are copper and aluminum.

Copper is more conductive, meaning it can ensure a faster process of making ice balls. However, copper presses are several times more expensive than aluminum ones, which made the latter a more popular option.

Aluminum is known as a runner-up metal in conducting heat, ranking just behind copper. In addition, aluminum is the most cost-efficient material to use in an ice press, so there’s no surprise that it’s so popular.

It’s Time To Start Making High-Quality Ice Balls

At BF TECH, we have eleven years of experience producing high-grade ice making equipment. We take pride in our sphere ice press that allows you to make perfect ice balls. It is manufactured from the premium quality aluminum, which makes it a highly productive and affordable option. You can choose a ball size from 40 to 70 mm (1.5 — 2.7 inches).