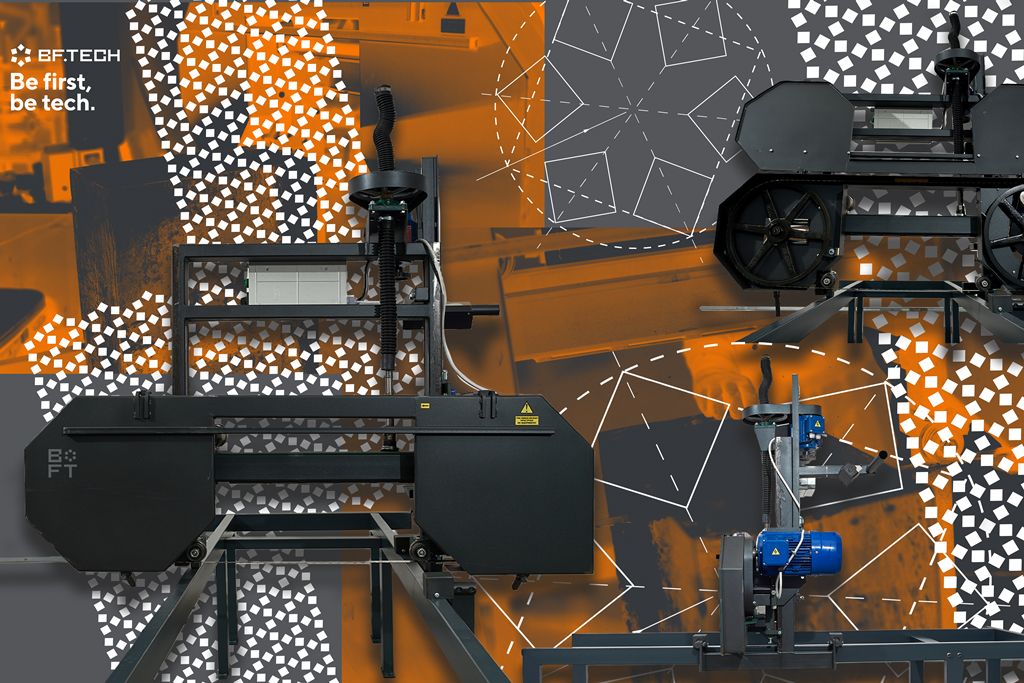

What is a Band Saw Used for? The Essential Guide for 2025

The bandsaw is an electric or battery-powered cutting tool that features a long, sharp blade consisting of a continuous band of toothed metal. It’s stretched between two or more wheels and appreciated for its precise cuts essential in woodworking and metalworking shops.

But beyond these common applications, what is a bandsaw used for?

Intricate artistic work, commercial manufacturing, and ice cutting are some of the areas it excels, too.

In this article, we will give you the answer to the question ‘What is a band saw used for?’ and talk about how to use a band saw, the most common band saws types, and their applications.

Versatile Applications of Bandsaws in Various Industries

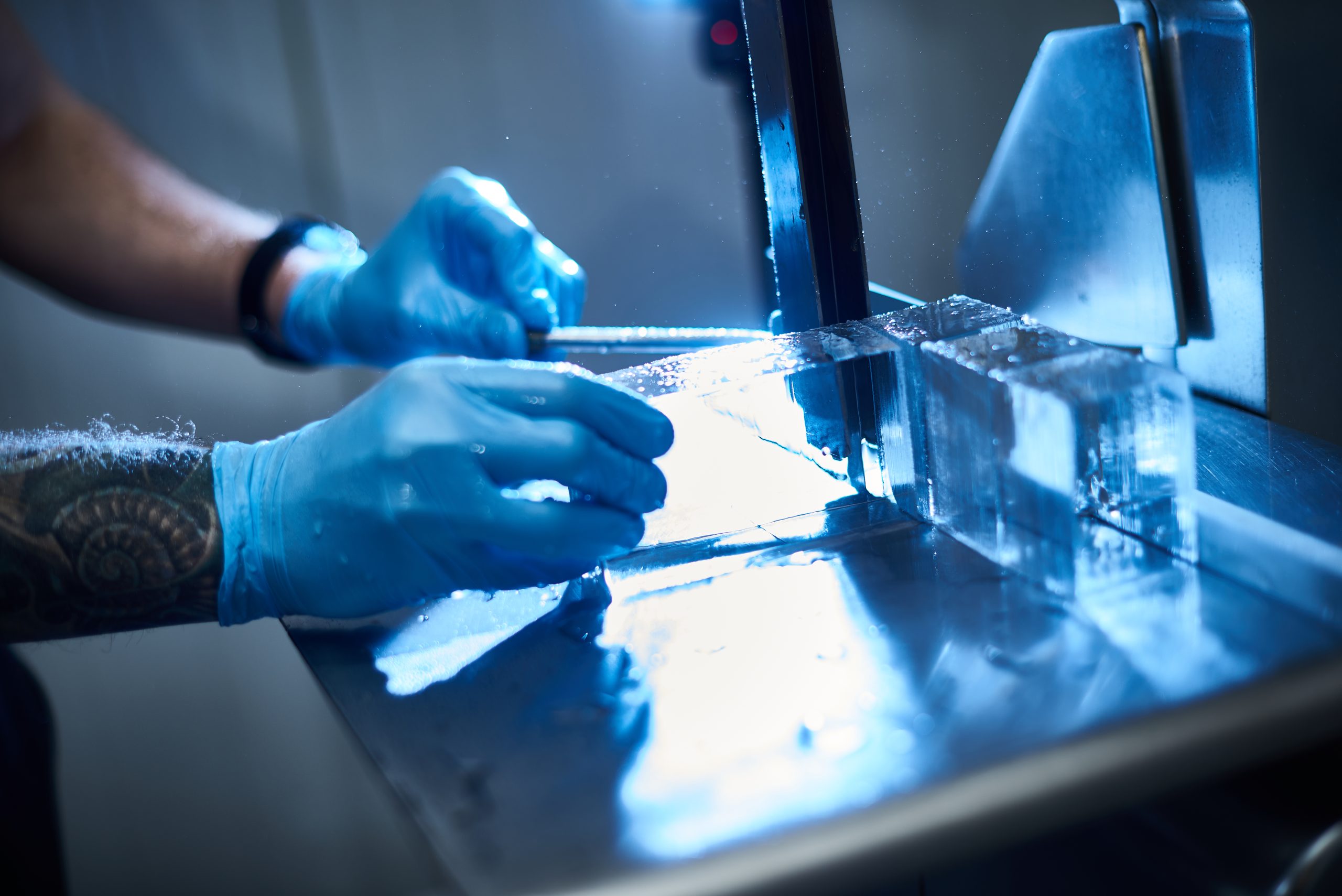

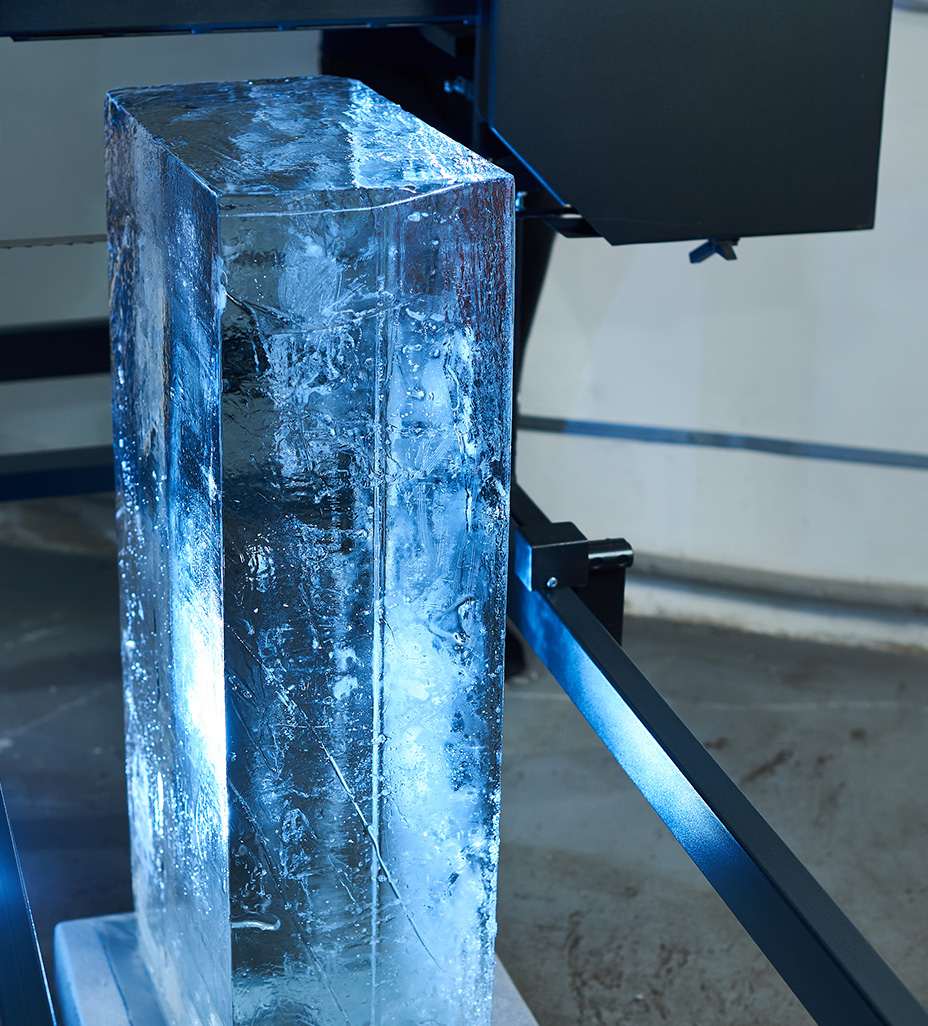

So, what are band saws used for? In industries where you’d least expect it, bandsaws find unique use cases you probably didn’t know about. For instance, ice cutting needs laser precision and efficiency — which this tool delivers.

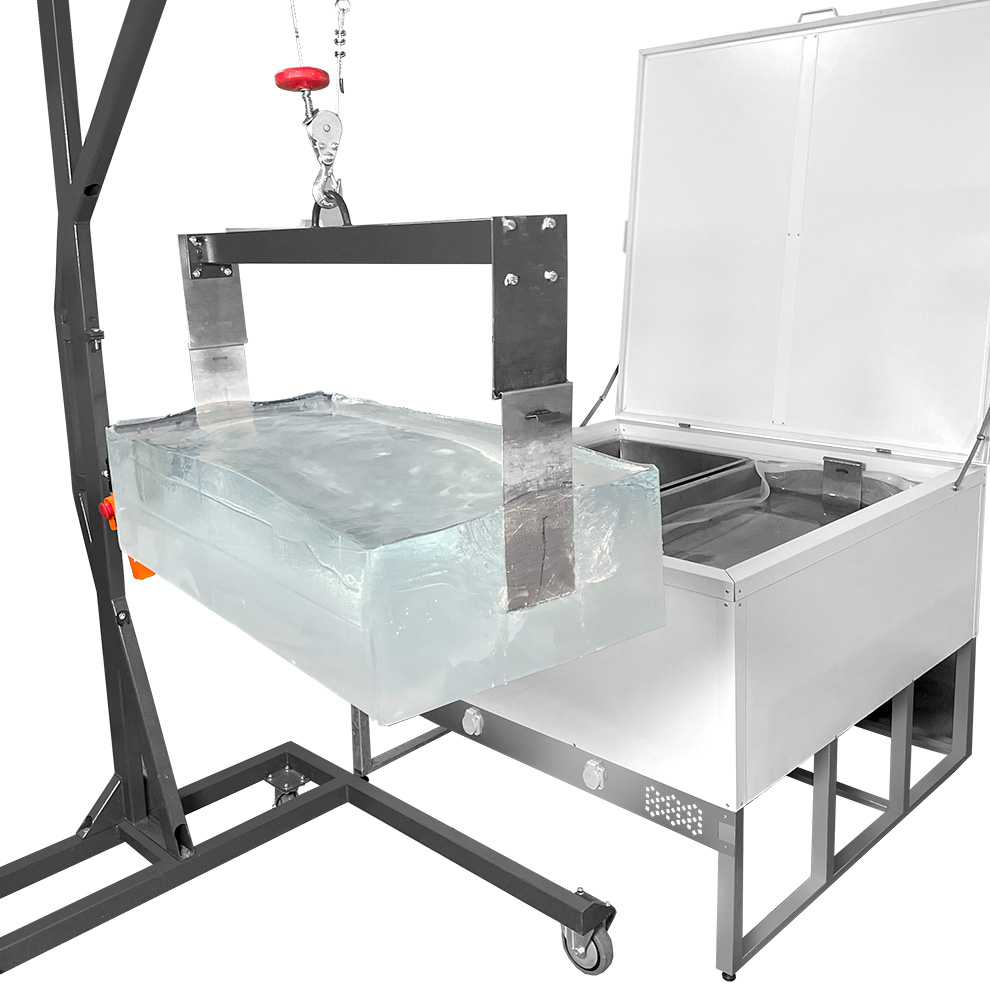

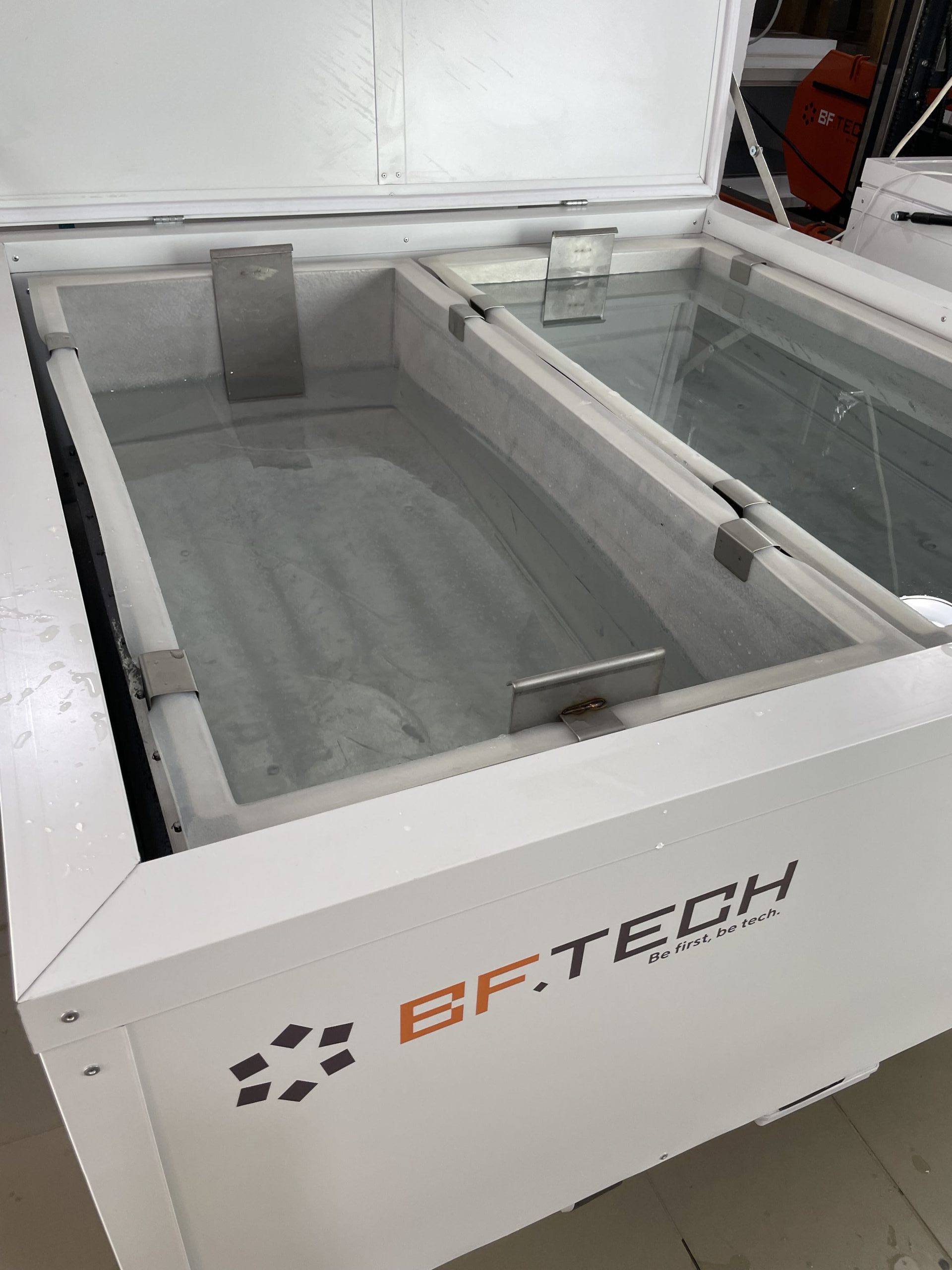

For example, the BF Technology ice-cutting saw was specially made to cut ice blocks into slabs or cubes, so we can see how adaptable and efficient it can be in specific scenarios.

Besides, band saw is an ideal tool and has a variety of applications among industry experts in such production environments as lighter construction, workpiece stationary, design centers, woodworking, and metalworking industries, metal fabrication shops, metal shops, and many more.

The Top 5 Common Uses for a Bandsaw

Looking at different band saws types reveals their versatility stems from the numerous sizes and blades. Today, bandsaw uses span across numerous industries. Here are just a few of them:

Precision Woodcutting

Woodworkers love them because they can execute straightforward or complex cuts in a piece of wood with precision without initial cuts or setups required by other saws. Straight, curved, or irregular— you can get any shape you need.

The thinner blades move smoothly allowing for tight curves in pieces of wood while other saws with wide blades struggle to achieve as much detail. This precision benefits joinery creations like tenons and dovetails that need exactness at all times. The common types of versatile machines expand craftsmen’s creativity boundaries along with their craftsmanship skills.

Complex Metal Shaping

For metalworkers, bandsaws excel at executing intricate shapes and resawing tasks of slicing metals into thinner pieces. The ability to adjust the correct blade types and speed according to the type of metal being cut allows for precise actions without compromising the integrity of your material. Plus, you can use them on various types of metal like aluminum, steel and copper, making them essential for complex shapes and forms.

The clean cuts they make and their efficiency in dealing with a variety of sizes of metal significantly reduce the need for secondary finishing processes — saving time and other resources in a fabrication project.

Intricate Artistic Creations

When it comes to artists, there’s no shortage of possibilities for these essential tools. They enable detailed sculptures from a variety of materials like wood, metal, or plastic. And they can make intricate cuts that are perfect for transforming these raw materials into art.

Wooden puzzles or jewelry pieces can be crafted from metal while models can be sculpted from almost any material you can think of. The versatility these tools offer to creators is immense with their complex designs able to bring imaginative visions closer to reality.

Commercial Manufacturing Processes

Consistency and accuracy are two of the most important aspects of commercial manufacturing. With a wide array of bandsaws, manufacturers are able to cut materials into specific sizes accurately as well as get a variety of cuts and complicated shapes. This is crucial in ensuring that products come out the same across each batch.

Bandsaws can handle just about any material that they’re given, whether it’s wood, plastic, metal or non-ferrous metal, or soft material, and this versatility makes them a great asset for manufacturing settings.

They are particularly useful in producing parts that fit together well, as this is often an important quality control aspect when making products. Bandsaws work quickly and are reliable too, so companies can maintain their high production rates and standards whilst still minimizing waste as much as possible.

Ice Cutting

Now let’s get to the question ‘What is a bandsaw used for?’ Whilst bandsaws seem best suited to woodworking and metalworking tasks, they have become increasingly useful for ice cutting, too.

Gone are the days of using chainsaws to turn blocks of ice into smaller pieces; this process was slow and dangerous with a high risk of accidents happening.

Now, you can get specially designed bandsaws that cut through huge ice blocks with ease. The speed at which this equipment works means that businesses can save time on turning bulk ice into usable pieces for different applications such as culinary displays, ice sculptures, and more. It also makes the process much safer.

Features of different Bandsaws

For different projects or industrial requirements, you will need different types of bandsaw features in order to make your task easier.

Let’s move on to the question ‘What do you use a bandsaw for?’ based on the features.

Here are some key features which separate different kinds from each other:

Blade Size and Type

The size and type of blade inside can mean everything when choosing a bandsaw. Thickness, configuration, and width all play a part in how accurately your cuts will be made on curves or straight lines.

Thicker blades with wider widths and fewer teeth per inch (TPI) work best when making straight cuts or resawing tasks, whilst narrower ones with a lot of TPI work well for more intricate details.

Cutting Capacity

Cutting capacity is very important to consider when wanting to cut through bigger materials. Thus, larger bandsaws will be able to accommodate thicker and wider materials.

Power and Motor Size

The size of the motor directly influences the power of the bandsaw. Machines with stronger motors can cut through tougher materials, such as metal or thick wood.

Table Size and Features

A larger table will be able to give you better support when trying to cut up larger pieces of material, meaning it would be perfect for big projects. Some tables can tilt at an angle too, giving you even more cutting versatility which could come in handy depending on what kind of project you’re working on.

Throat Depth

The distance from the blade to the frame of the saw is called throat depth. It determines how wide you can cut a piece of material with a bandsaw. Smaller depths limit what you can do while bigger ones give you more freedom to cut wider materials, making it more versatile.

Speed Settings

Changeable speed settings allow users to modify the blade’s velocity to suit the material being cut. Lower speeds are used in cutting metals and plastics to prevent overheating, while higher speeds benefit woodworking. This feature gives bandsaws freedom to work with various materials and cutting requirements.

Comparative Analysis: Bandsaws vs. Other Cutting Tools

Bandsaw vs. Circular Saw

Bandsaws and circular saws have different use cases. Utilizing long, thin looping blades, bandsaws can make precise cuts in curves and shapes. They are well suited for larger stocks and less wasting material due to a lack of thickness in their blade kerf.

In comparison, circular saws prioritize speed and cleanliness as they can quickly produce straight cuts using their large round blades. While providing a cleaner surface on cuts, these saws cannot handle working with larger pieces because their blade size is limited.

Bandsaw vs. Jigsaw

Portable jigsaws that excel at complex curved cuts have an edge over bandsaws when it comes to tight spaces, which is something looping blades just can’t compete with.

However, despite their weaknesses in flexibility, bandsaws work splendidly on thick materials whereas jigsaws falter. They are a perfect fit for workshops where you need better control over larger or thicker materials.

Bandsaw vs. Table Saw

Table saws fail to match the wide range of cuts bandsaws can perform due to their limitations on only making straight lines with precision edges. They lose in versatility when compared to adjustable tables or variable speed settings like what’s found on most band models.

Despite this disadvantage, there is no denying that table saws provide the cleanest of all straight lines and should be used accordingly for projects requiring exact fits or sharp cornering.

However, bandsaws win in making curved cuts with much more accuracy and being able to execute deeper ones. This makes them the superior choice for a wider range of projects.

Choosing the Right Tool for Your Project

When choosing the right tools, think about material size, what kind of cuts are required, as well as how precise you actually need to be. Bandsaws have far more capabilities when it comes to versatility and precision in a variety of cutting techniques than any other saws.

Circular saws simplify quick straight cuts, while jigsaws are unmatched in portability and intricate slender cuts on smaller materials or thicker pieces. Table saws don’t hold a candle to bandsaws but they do outperform them on straight-line precision and play an important role in work with larger materials requiring depth control.

Expert Insights: Maximizing Efficiency with Bandsaws

Working efficiently does not only mean knowing how to operate your saw properly. It also involves understanding the limits and capabilities of your type of band saw, learning when certain blades should be used, and following all safety precautions religiously.

There are multiple steps that can transform your approach to working with bandsaws into something more special than the average user would take. This will surely pay off by delivering high-quality results from your equipment every single time you use them.

To start, it’s key that you know your bandsaw in and out. Each kind has its own set of strengths, from the motor’s power to how deep a cut it can make. Some are just more versatile when it comes to blade adjustments. Getting to know these aspects well will help you get the most out of a variety of machine bandsaws.

The efficiency of this versatile cutting tool comes from the proper blade. Having the right durable blade can be the difference between an alright cut and an amazing one. Factors like blade width, tooth pitch, and material are vital to consider:

- Wider blades are a popular choice and great for straight relief cuts and resawing because the blade tracking provides stability and accuracy. A narrow blade, however, is better at cutting curves or intricate shapes.

- The type of cut you want to make and how thick your material is determines the best tooth geometries. Finer common teeth with bigger tooth space are better for detailed work on thin materials, while coarser teeth are ideal for faster cuts through thicker stock like a piece of metal.

- High-speed steel, bimetal, and carbide-tipped blades as well as teeth of blades all have different benefits when they’re used in the right context. They also affect things like durability and cutting performance. So, picking the right one can seriously impact how long your blade lasts.

Keeping up with maintenance is key in the treatment of blades. Cleaning it regularly and checking for damage will keep your cutting efficiency where it needs to be as well as extend the blade life.

But of course, safety comes first, always. Safety features and measures include using blade guards, making sure you’ve got proper tension on them, and wearing protective gear ear protection, like safety goggles or gloves (or both). Keeping your workspace clean so there’s good visibility and light around your bandsaw can also prevent accidents from happening in the first place.

How to enhance efficiency though?

- Changing how fast you feed material through based on its type and what kind of blade you’re using can optimize efficiency by lowering the risk of deflection and smoothing out cuts.

- Planning out how to cut something to waste as little material as possible saves more than just resources — it saves time, too.

- If you get supports or jigs that match what you’re going for in terms of material being cut, it’ll improve accuracy on top of making it easier to manage large or difficult items.

Future of Bandsaws: Emerging Technologies and Trends

The future of bandsaws is very promising.

Automatic bandsaws handle materials differently to get the job done right. They have the power to control cutting speed, blade pressure, and feed rate as they work on various materials. This makes a cleaner end cut while also saving you money by reducing waste.

New designs for saws that use more efficient energy and smart technology (usually IoT) are coming out too. They will be able to monitor themselves for necessary maintenance so you don’t have to worry about it.

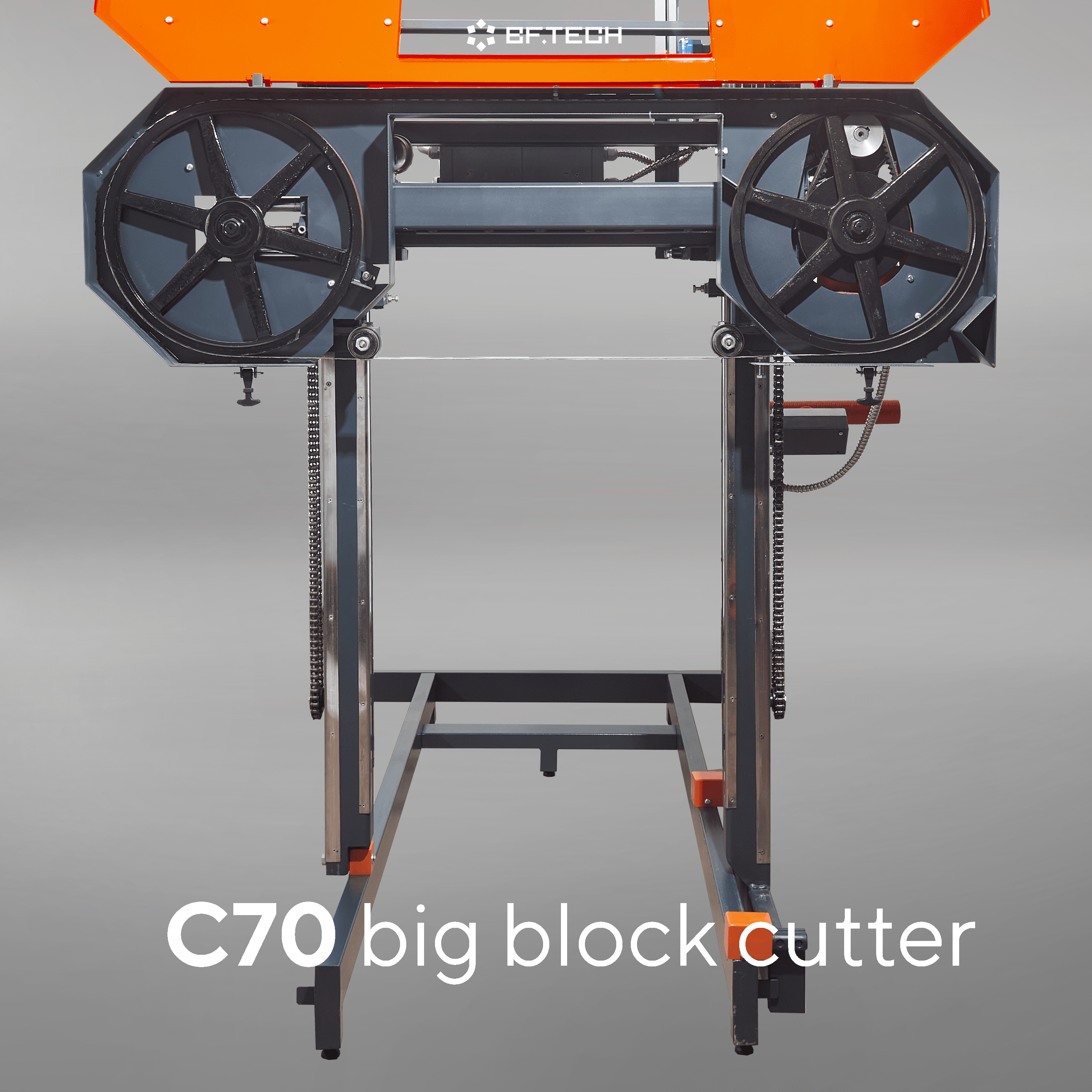

A great example of that is the BF Technology ice block cutter C70 which was designed specifically for ice cutting. This must have tool is remote controlled so no one has to be near it when it’s in operation and can be lifted safely with electricity instead of manpower or hydraulic piston (a real game-changer!), and is compact enough to take up less space but still packed a bunch in safety and efficiency features.

The Role of Bandsaws in Custom Fabrication

Bandsaws are a critical tool for custom fabrication. It provides the flexibility and precision you need to make a project completely on your own. They’re able to make precise cuts in various materials, which is every designer’s dream.

The versatility of bandsaws is matched only by their wide range of blade types and sizes. There’s no other tool that can offer such precise dimensional cuts, curves, and angles on complex designs.

As more demands for customization come in, the role of bandsaws in custom fabrication will continue to grow even further. Artisans and manufacturers everywhere will be able to bring their wildest imaginations into reality with this amazing tool.

Maintenance and Troubleshooting Common Bandsaw Issues

Maintenance and troubleshooting help your bandsaw last longer and perform better. Cleaning, lubricating, and looking at the blade regularly can prevent wear on the parts and blade breakage so that everything runs nice and smooth.

Adjusting the tension of the blade and aligning the wheels is usually all it takes to fix common problems like blade drift, broken blades, inaccurate cuts, or excessive noise.

And make sure you’re using the right blade type, tooth load, and speed for what you’re cutting. All this will ensure that your bandsaw keeps running efficiently, you don’t have non-cutting teeth, and you are making quality and precise cutting.

FAQs

What makes a bandsaw different from other cutting tools?

The defining feature of a bandsaw is its continuous loop blade. Traditional tools have blades that stand still; others are run by motors in which their blades spin around like helicopter rotors. But a bandsaw's blade moves in a constant loop from one wheel to another. This unique design allows you to smoothly cut curved shapes and create intricate designs with ease.

Can bandsaws be used for materials other than wood and metal, like ice?

While wood and metal might be some of the most common things people cut with their bandsaws, they aren’t the only materials that work with these powerful tools. Some specially-made band saws even allow people to cut ice blocks or structural steel.

What is a band saw best used for?

A bandsaw truly excels at precision cutting jobs where versatility matters more than raw power or maximum depth (both areas where other tools like table saws dominate). Its ability to handle so many different types of materials makes it useful not just in woodworking shops but also in machine shops full of metal workers or sculptors who focus on ice art.

What can be done with a band saw?

A few ideas for using different types of band saw (horizontal band saws, vertical band saws, portable power tool versions, and others) include: Furniture making Cabinetry work Finishing a carpentry project Precision shape cuts in metal Artistic, intricate metalwork Cutting ice blocks into shapes for other projects