How to Start an Ice Business from Scratch

Think starting an ice business is as simple as buying a machine and waiting for customers? Think again. The ice industry is more competitive than ever, and success depends on smart and careful planning, understanding what your customers actually want, and — here’s the kicker — choosing technology that works as hard as you do.

Whether you’re eyeing the ice delivery business scene or considering other ice ventures, understanding how to start an ice delivery business properly can make the difference between barely scraping by and building something that actually makes money.

Understand the Ice Market

Here’s the thing about business ideas in the ice making business — you can’t just jump in blind. Your local market has its own personality, and you need to get to know it. We’re talking about everyone from bartenders crafting smoke ice cubes for drinks to construction crews who need massive amounts of ice to keep concrete from setting too fast in summer heat. Then there are convenience stores stocking their freezers and event planners who panic-buy ice at the last minute.

The numbers tell an interesting story. The global commercial ice machine market is heading toward $4.2 billion by 2028, and that growth isn’t slowing down. But here’s what really matters: summer can triple your demand practically overnight, while winter months might have you wondering where all your customers went.

Your potential customers aren’t all the same, either. A high-end restaurant needs pristine ice that won’t water down their craft cocktails. A construction company just wants bulk ice that keeps their workers from overheating. Wedding planners need someone they can count on when they’re already juggling a thousand details. Each group has different expectations, and understanding these differences is what separates successful operators from the ones who struggle.

Explore Different Opportunities

The ice making business offers more paths than you might expect, and each one demands different business models on how to start an ice delivery business and technology approaches.

Let’s break down what’s actually out there.

Ice Making Business

An ice making business is all about production and wholesale. You’re making ice blocks or cubes to sell to restaurants, bars, grocery stores, and other businesses that go through ice like water. The upfront costs can be steep, but once you’ve got solid contracts with commercial clients, the revenue becomes pretty predictable.

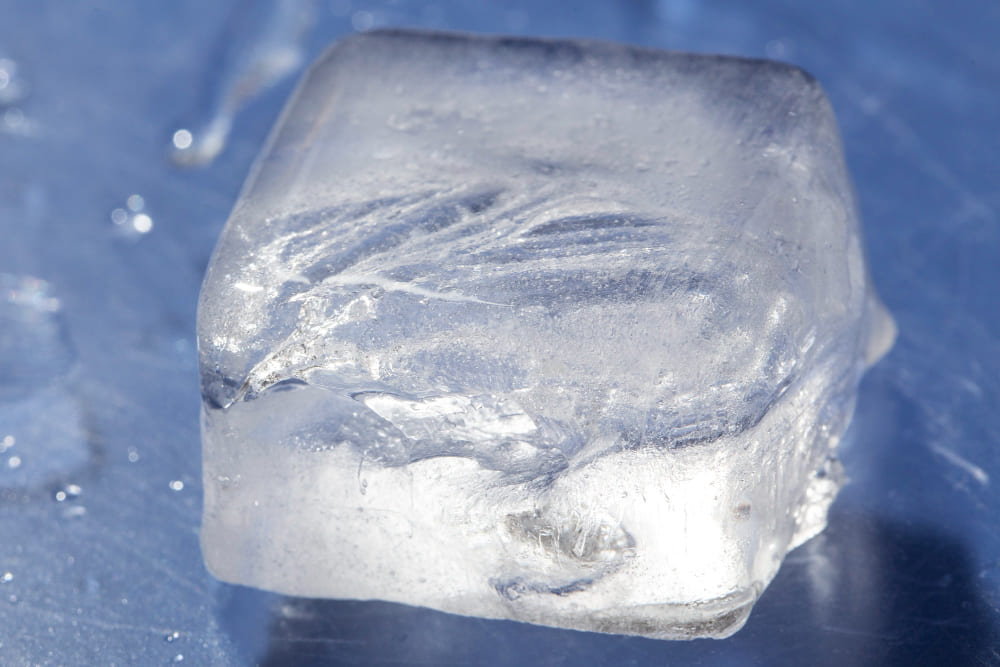

Success here comes down to two things: making ice efficiently and making it consistently good. Modern ice block maker machine technology has gotten impressive — we’re talking crystal-clear, super-dense ice blocks that restaurants actually pay premium prices for. Take the P300 model, which cranks out four 130kg ice blocks per cycle. That’s serious production power for ice making business operations serving multiple commercial accounts.

The tricky part? Timing your production just right. Make too much during slow periods and you’re watching money melt away. Make too little when demand spikes and you’re disappointing customers who won’t forget. Smart ice making business operators now use forecasting software that talks to their equipment, automatically adjusting production based on expected demand. It’s like having a crystal ball, but actually useful.

Ice Vending Business

The ice vending business is where automation meets opportunity. These machines work around the clock without needing anyone to run them, which makes them perfect for busy locations where traditional retail space is either too expensive or just not available.

Today’s ice vending machines are basically small businesses in a box. They take credit cards, send you alerts when something’s wrong, and even clean themselves. The real skill is in picking locations — gas stations, apartment complexes, and recreational areas tend to generate the best returns for ice vending business setups.

What’s attractive about vending is the profit margins. Without labor costs eating into your revenue and machines working 24/7, you can often beat traditional retail models. But here’s the catch: when a machine breaks down, every hour of downtime is money walking away. You need reliable equipment and a maintenance plan that actually works.

Ice Delivery Business

An ice delivery business brings ice directly to customers who need it. This works especially well for event planners juggling multiple vendors, small restaurants without enough freezer space, and homeowners throwing parties who suddenly realize they need way more ice than they thought.

Running an ice delivery business means thinking about logistics as much as ice. You need GPS systems to track your drivers, refrigerated trucks that actually keep ice frozen, and software to manage customer orders and route optimization. Get the routes wrong, and you can lose money on deliveries that should be profitable.

Other ice vending business companies combine production with delivery, giving them more control over quality and margins. Either approach can work, but they require different skill sets and technology investments when figuring out how to start an ice business.

Select the Right Equipment

This is where most people either set themselves up for success or create years of headaches. Choose wrong, and you’ll be fighting your equipment instead of growing your business. Choose right, and you’ve got the foundation for something that actually scales.

Invest in a Reliable Ice-Making Machine

Your ice machine choice affects everything: how much ice you can make, what quality you can deliver, and how much it costs to operate. Block ice makers have some real advantages for commercial operations, especially their ability to produce that dense, slow-melting ice that customers are willing to pay more for.

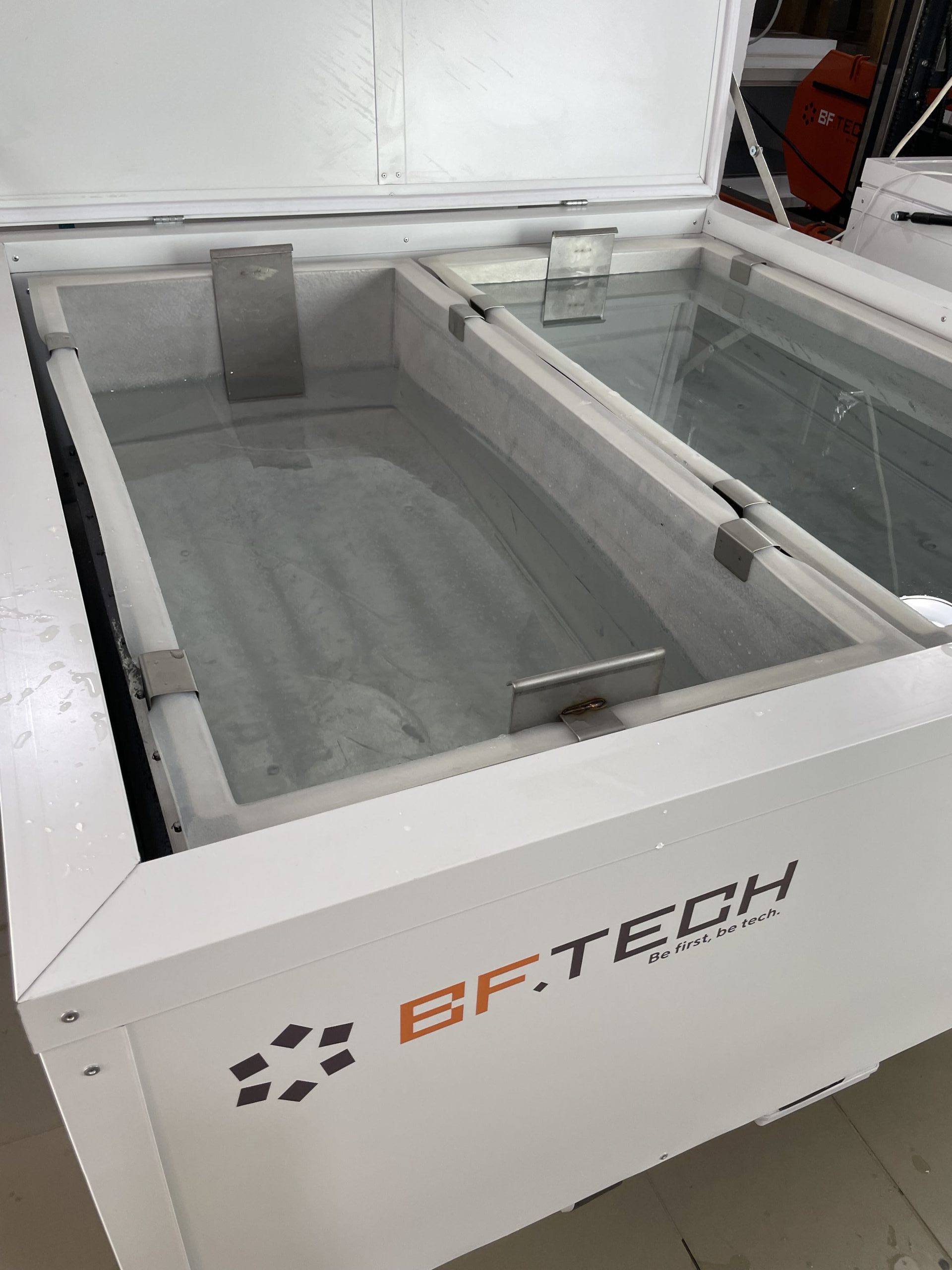

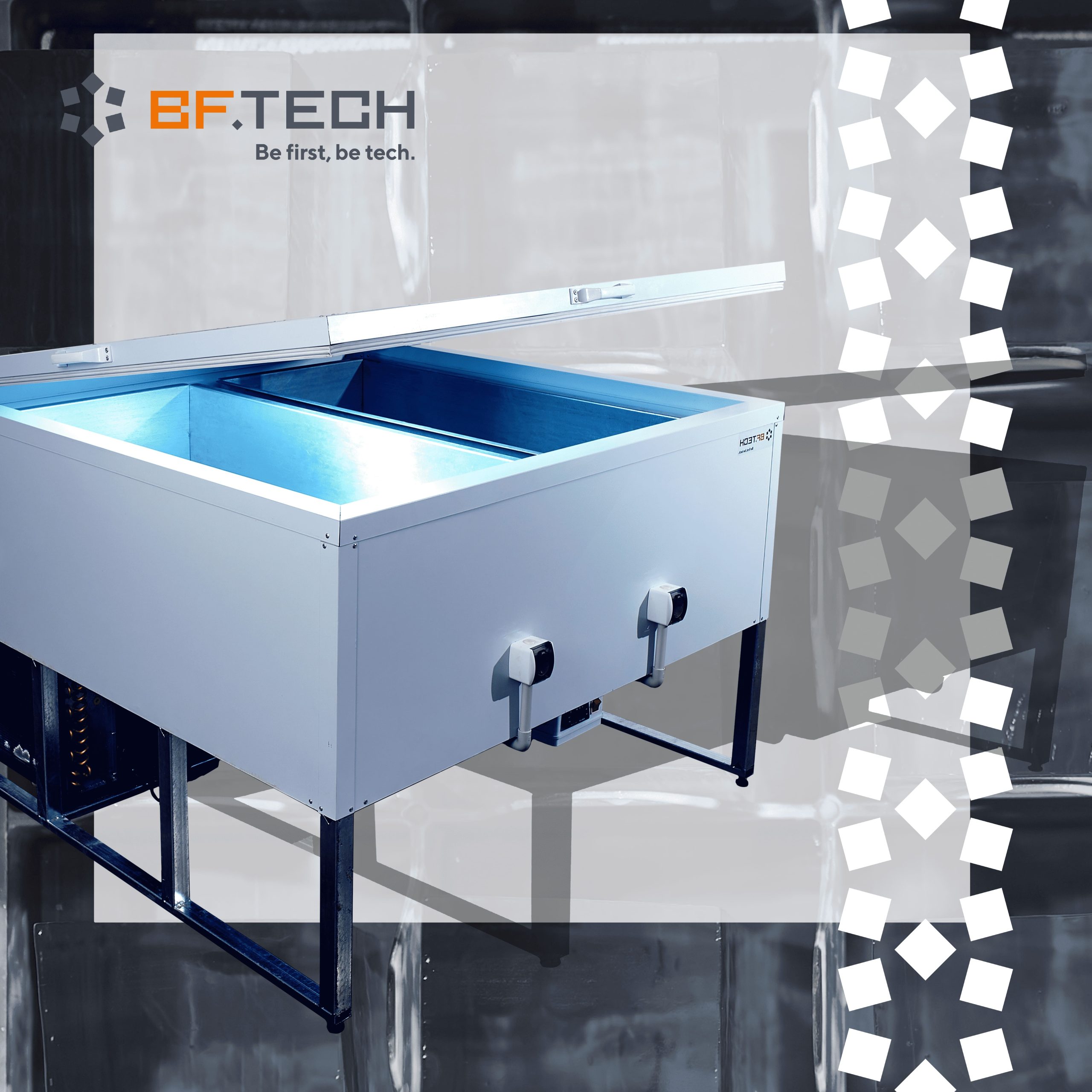

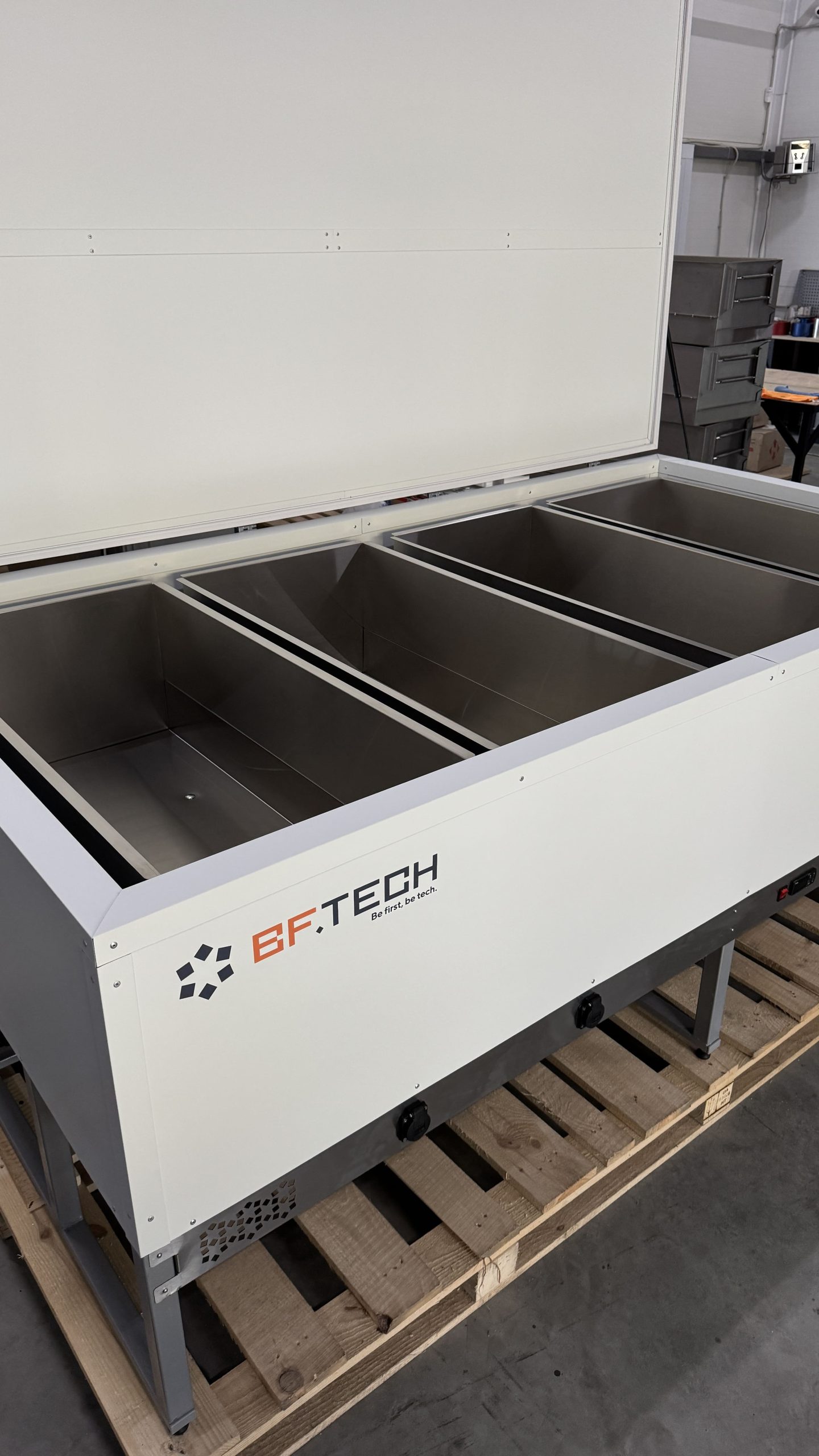

- The P150 model hits a sweet spot for smaller to medium operations. Two 130kg blocks per cycle, energy efficient, and built with polyurethane insulation that lets it work in hot conditions. Whether you’re in Arizona or Alaska, this machine adapts to your environment instead of fighting it.

- Need more production? The P300 doubles your output with four blocks per cycle. Both machines come with LED displays showing exactly what’s happening and multiple protection systems that prevent the kind of breakdowns that kill your busy periods.

- For smaller operations or HoReCa markets (hotels, restaurants, cafes), the P30 model delivers the same quality and reliability in a compact package that doesn’t overwhelm smaller spaces or budgets.

Consider Additional Tools and Technology

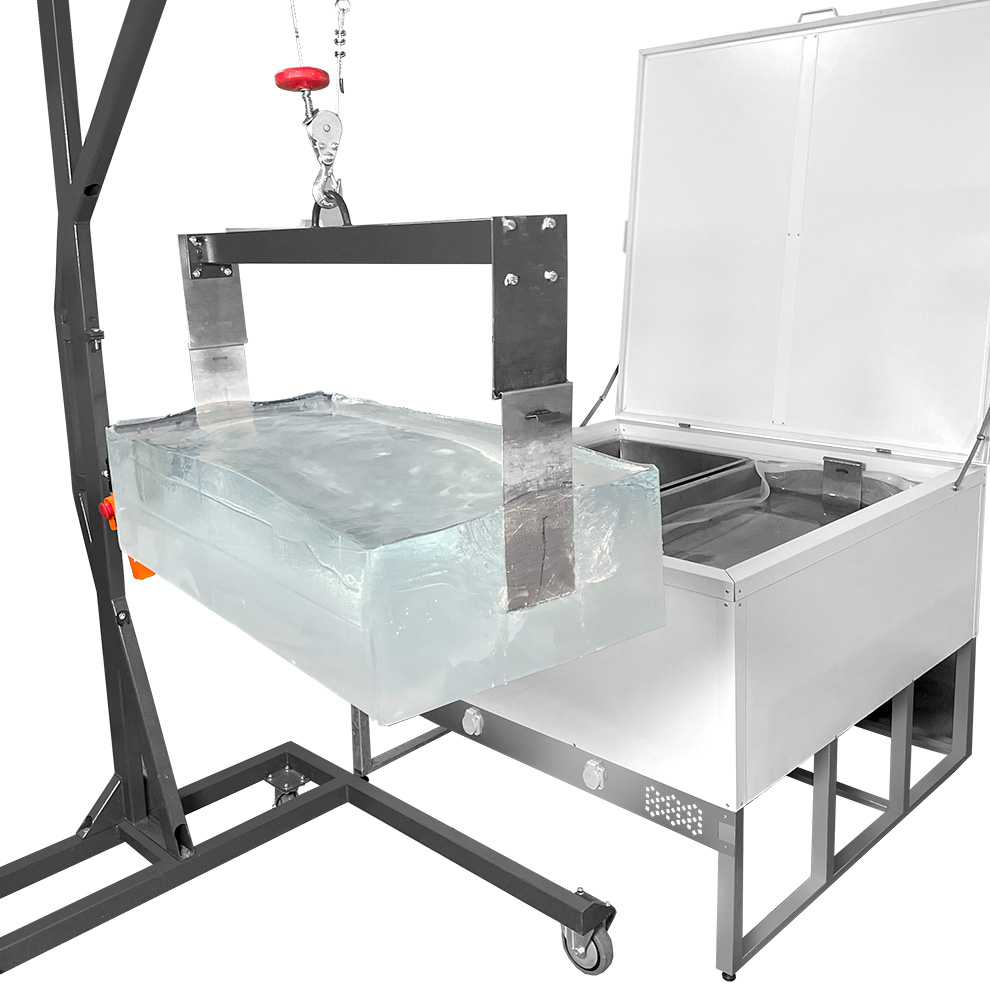

The ice machine is just the beginning. You’ll need ice saws for cutting large blocks into customer-friendly sizes. Presses — pneumatic or hydraulic — let you create specialized shapes for premium applications that command higher prices.

Don’t overlook the handling equipment: ice carts designed for the job, lifting beams that actually work, storage containers that maintain quality during transport. Too many operators skimp on these “extras” during setup, then spend months figuring out why their operations feel clunky and inefficient.

Digital integration is where things get interesting. Temperature monitoring with remote alerts means you find out about problems before they ruin a batch of ice. Inventory management software prevents the feast-or-famine production cycles that waste money and frustrate customers.

Focus on Quality, Efficiency, and Sustainability

Long-term success isn’t just about making ice — it’s about making good ice efficiently while building practices that customers respect and that keep your costs manageable.

Implement Quality Control Measures

Quality starts with your water source. Bad water makes bad ice, and bad ice loses customers fast. Filtration systems aren’t optional if you’re serving restaurants and bars where ice directly affects how drinks taste. Regular water testing catches problems before they become customer complaints.

Temperature control throughout your entire process — production, storage, transport — keeps ice quality consistent. Automated monitoring systems alert you when temperatures drift outside acceptable ranges, preventing product loss and the customer calls that follow.

Documentation matters more than you might think. Tracking production batches lets you respond quickly to quality issues and shows commercial customers that you take consistency seriously. Professional customers notice these details.

Invest in Technology and Maintenance

Modern ice equipment includes control systems that optimize energy use while maximizing output. These systems automatically adjust cooling cycles based on ambient conditions, reducing your electricity bills while maintaining production schedules.

Preventive maintenance programs protect your equipment investment and prevent breakdowns during your busiest periods. Many manufacturers offer maintenance contracts covering regular inspections, parts replacement, and emergency repairs. Consider the math: scheduled maintenance costs far less than emergency calls during peak season.

Training your team properly pays dividends. Staff who understand equipment capabilities and maintenance procedures catch potential issues early, turning minor problems into minor fixes instead of major expenses.

Schedule Regular Equipment Maintenance

Daily cleaning prevents bacterial growth and maintains ice quality. Weekly inspections identify wear patterns and mechanical issues before they become failures. This isn’t exciting work, but it’s what separates reliable operations from ones that struggle with unexpected downtime.

Seasonal maintenance becomes critical before demand peaks. Comprehensive system checks, refrigerant verification, and component replacement ensure your equipment performs when revenue depends on consistent production.

Upgrade Technology for Efficiency Gains

Technology upgrades often pay for themselves quickly through reduced energy consumption, increased capacity, or improved product quality. Upgrading to modern, eco-friendly refrigerants often improves efficiency while reducing environmental impact.

Automation reduces labor requirements while improving consistency. Automated cleaning cycles maintain sanitation without manual intervention. Production scheduling software optimizes output based on demand forecasts, reducing waste and maximizing profitability.

Common Mistakes to Avoid When Starting an Ice Business

Learning from others’ mistakes is cheaper than making your own. Here are the big ones that trip up new operators.

Underestimating Demand

Many new business owner types underestimate how much seasonal demand varies. Summer demand can be three times winter levels, but equipment sized for average demand leaves money on the table during peak periods. Equipment sized for peak demand sits idle during slow periods.

However, premium ice produced using BF Tech equipment is an exception — it experiences almost no seasonal drop. In fact, winter can even be considered its high season. Cocktails made with this type of ice aren’t typically served on sunny terraces during a heatwave, but rather enjoyed in speakeasy bars when it’s cold outside. This stabilizes sales for the producer and becomes a key survival factor during the off-season.

Business licenses and permits can shut you down completely if you get them wrong. Research local regulations thoroughly and get all documentation sorted before you start operations, not after you’re already running.

Choosing the Wrong Equipment

Buying based on upfront cost alone creates ongoing profitability problems. Quality equipment costs more initially but provides better reliability, lower operating costs, and superior product quality that commands premium prices. Cheap equipment rarely stays cheap once you factor in repairs, downtime, and customer losses.

Ignoring expansion capabilities limits growth options. Equipment that can’t scale with business growth forces expensive replacements as you expand. Plan for success, not just survival.

Ignoring Maintenance and Storage

Inadequate storage compromises ice quality and increases waste. Proper insulation, temperature control, and contamination prevention are essential for maintaining product integrity from production through delivery.

Skipping maintenance schedules leads to equipment failures, production interruptions, and expensive emergency repairs. Regular maintenance costs less than emergency breakdowns during busy periods.

Poor inventory management creates either stockouts that disappoint customers or excess inventory that melts before sale. Proper forecasting and production scheduling prevents both scenarios.

Conclusion

Building a successful ice business goes well beyond simply producing frozen water — it’s about combining smart planning, reliable equipment, and day-to-day operational excellence. Whether you decide to focus on wholesale production, vending operations, or delivery services, everything comes back to choosing the right technology and putting systems in place that actually deliver results.

The path to profitability starts with truly understanding your local market, then matching your equipment choices to what your operation actually needs while staying focused on quality and efficiency. Today’s ice production technology opens doors to better energy efficiency, higher production capacity, and superior product quality that can set your business apart from the competition.

Don’t overlook the fundamentals: securing proper business licenses, arranging financing through options like a business loan, and developing solid operational procedures are every bit as crucial as picking the right equipment. The ice vending business industry holds real promise for entrepreneurs who are willing to put in the work on proper planning and invest in quality technology that supports their long-term goals.

FAQ

What type of ice machine is best for a small ice making business?

For small operations, the P30 model offers an ideal balance of production capacity and operational efficiency. Its compact design works in limited space while maintaining commercial-quality standards. The polyurethane insulation handles various operating conditions, and the LED display keeps you informed about operational status.

Is an ice making business profitable?

Yes, an ice making business can be highly profitable with proper planning and execution. Industry margins typically range from 40-60% for wholesale operations, with even higher margins possible for retail and specialty applications. Profitability depends on equipment efficiency, market demand, operational costs, and pricing strategies.

What is the difference between an ice making business and an ice delivery business?

An ice making business focuses on production and wholesale distribution to commercial customers, requiring significant equipment investment but offering stable, recurring revenue. An ice delivery business emphasizes logistics and customer service, delivering ice directly to end users. Many successful operations combine both models, producing their own ice while offering delivery services to bring ice to customers.

How do I maintain and clean an ice machine?

Proper maintenance and cleaning are essential for ice quality and equipment longevity. For detailed maintenance procedures and cleaning protocols, visit our comprehensive guide on how to clean an ice maker. Regular maintenance includes daily cleaning, weekly inspections, and seasonal comprehensive servicing to ensure optimal performance and product quality.