How do I decide which equipment I need to produce premium ice?

Ice is essential in many industries. It’s not just there to cool things down; it also helps preserve perishables, makes things look better, and can even be used in medical applications.

Many different ice equipment types have been made to meet these various demands, so your business will operate much more efficiently when you use the proper equipment.

Whether you work in hospitality or healthcare, there is a demand for all different kinds of ice.

The right machine can change how well your company functions daily depending on your needs. Recognizing this will help you choose what’s right for you and ensure your business can run at its best capacity.

We are sure you understand how to produce ice and are aware of some processes. However, let us explain the process in detail so you can understand exactly what you need or don’t need to buy or organize.

In order:

Block Machine for Ice Production

To produce ice cubes, you first need to create ice blocks. The choice of equipment is up to you.

P30

- Ideal for HoReCa (Hotels, Restaurants, and Cafes) environments or locations with limited space.

- Does not require a hoist or tilt cart.

- Produces 3 ice blocks of 51×26 and height 25-27 cm (20×10 and height 10.6 inches) in 3 days.

- Each block weighs about 35 kg (75 lbs), the total output up to 100 kg (220 lbs).

- Uses 30 liters (8 gallons) of clear water per tank, total 90 liters (24 gallons) per cycle.

- From one 3-day cycle, you can produce 750+ cubes (5x5x5 cm / 2x2x2 inches).

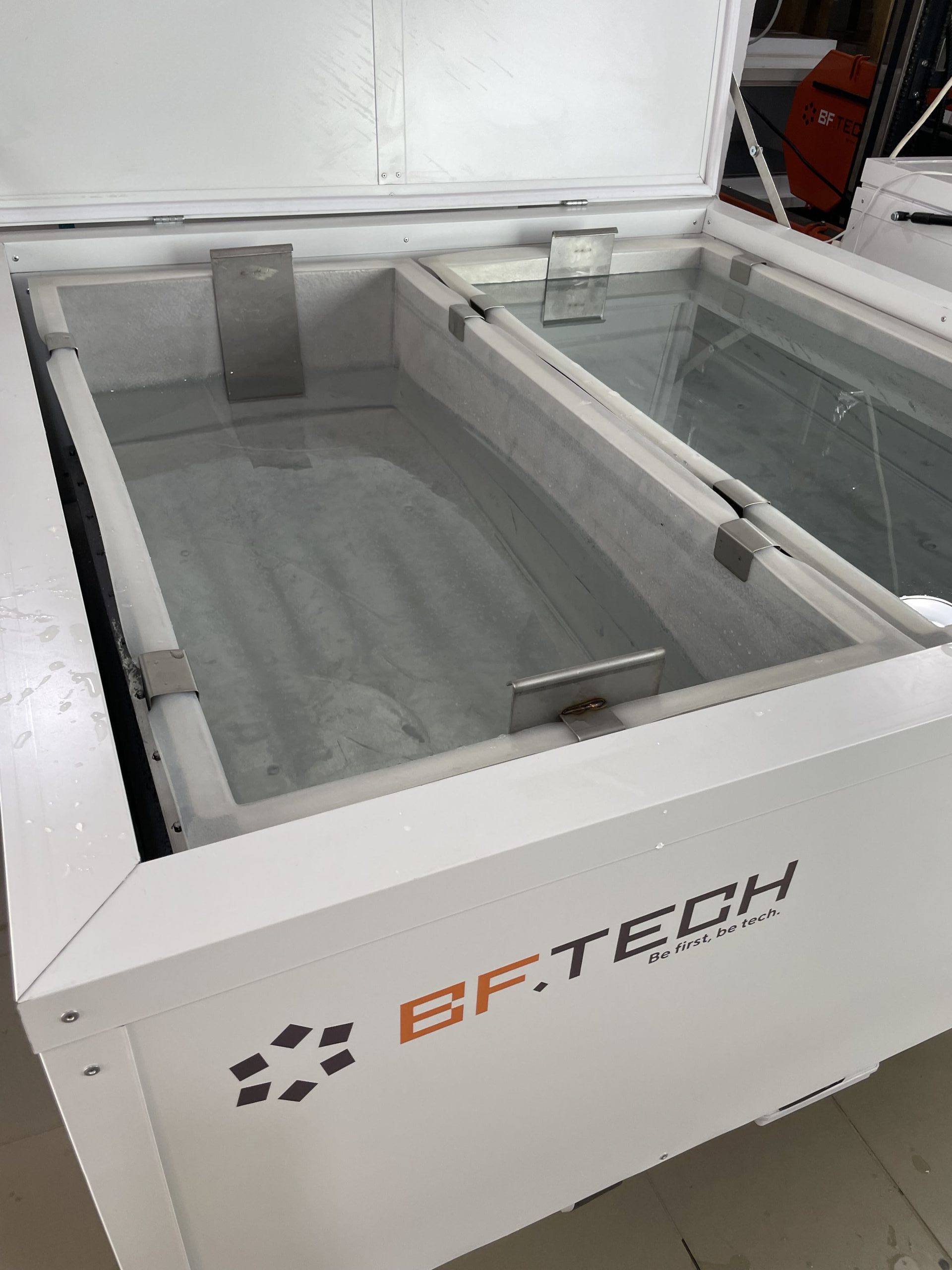

P150 (Basic Version)

- Produces 2 large ice blocks of 104×50 and height 25 cm (40×20 and height 10 inches) in 3 days.

- Each block weighs 130 kg (300 lbs), the total output up to 260 kg (600 lbs).

- Uses 150 liters (40 gallons) of clear water per tank, total of 300 liters (80 gallons) per cycle.

- From one 3-day cycle, you can produce 1800-2000 industry-standard cubes (5x5x5 cm / 2x2x2 inches).

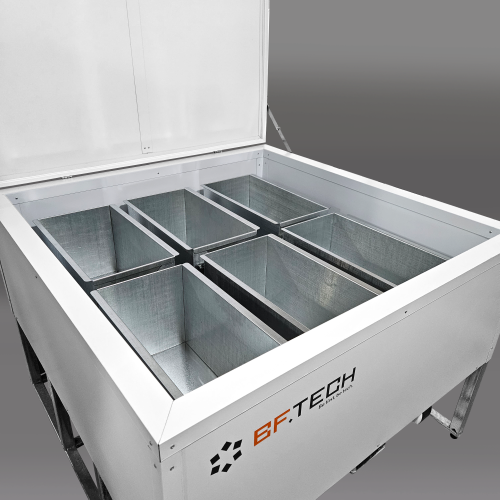

P150 (Modified Version)

- Equipped with six small tanks similar to the P30.

- Does not require a hoist or tilt cart.

- Produces 6 ice blocks of 51×26 and height 26-27 cm (20×10 and height 10.6 inches) in 3 days.

- Each block weighs 35 kg (75 lbs), the total output up to 200 kg (550 lbs).

- Uses 30 liters (8 gallons) of clear water per tank, total of 180 liters (48 gallons) per cycle.

- From one 3-day cycle, you can produce 1500+ industry-standard cubes (5x5x5 cm / 2x2x2 inches).

P300

- Designed for professional ice production.

- Produces 4 large ice blocks of 104×50 and height 25 cm (40×20 and height 10 inches) in 4 days.

- Consumes less power than two P150 machines.

- Each block weighs 130 kg (300 lbs), the total output up to 520 kg (1200 lbs).

- Uses 150 liters (40 gallons) of clear water per tank, total 600 liters (160 gallons) per cycle.

- From one 4-day cycle, you can produce 3600-4000 industry-standard cubes (5x5x5 cm / 2x2x2 inches)

Watch a demonstration of these machines. Separate videos for each model are available on our profile

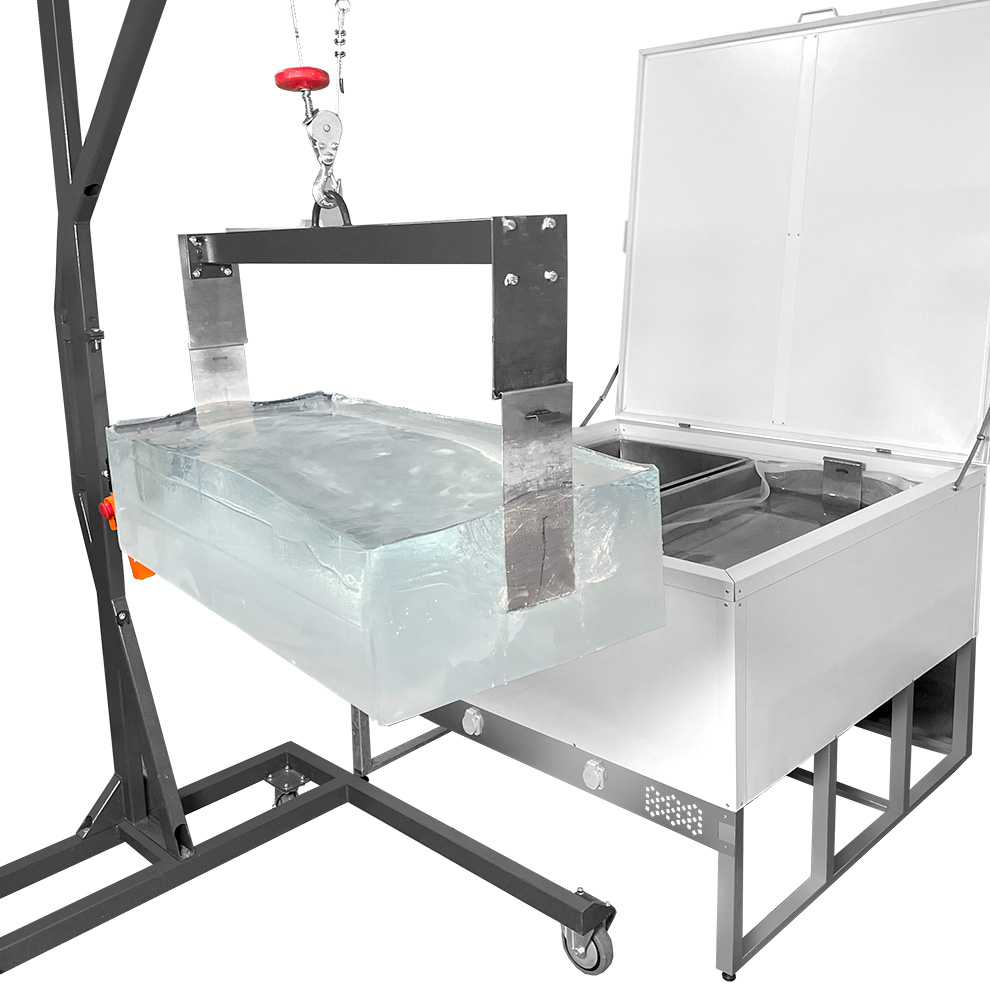

Hoist for Ice Block Removal

After the production of the ice block you have to remove it from the equipment. We use a small and compact electric hoist, it also performs many other tasks in production and even helps to install sculptures on installation sites due to the fact that we made it collapsible, but if you already have a crane-beam – it may not be necessary for you. Check it out on our Instagram!

Tilt Cart

This cart is used to lower the ice block and move it to any place (cutting, freezer, truck, etc.). It allows the ice block to be turned from horizontal to vertical and vice versa. Check it out on our Instagram!

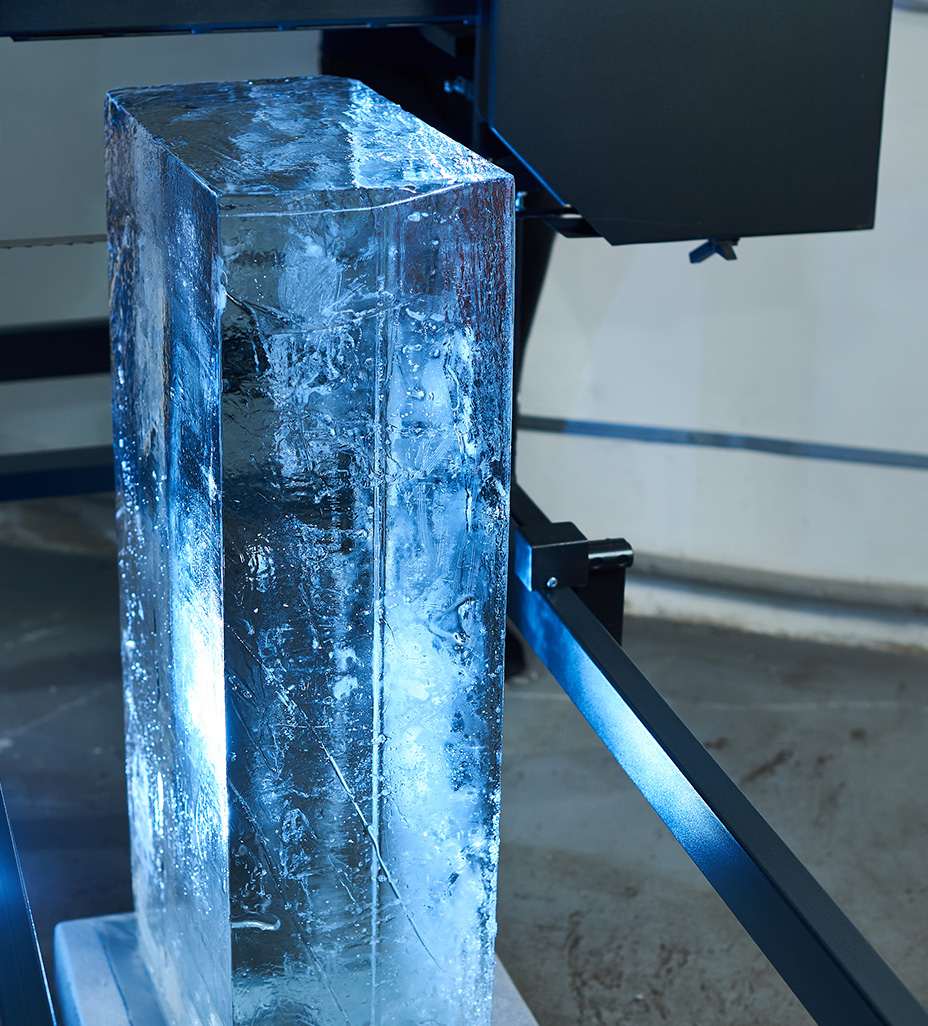

Cutting Ice into Slabs

After we get a block of ice, it needs to be cut into smaller pieces – ice slabs, which will later become cubes. There are two methods for this: manual cutting with a chainsaw (such as Makita, Stihl, etc.) or our saw C70.

Manual cutting is quite long and creates a significant consumption of ice, each slab must be cut off from a large block and then moved for cutting on a small saw, but if you do not have space for a large horizontal saw – this is the only option.

We haven’t worked like this for a long time, so the link to this method from our friends is here.

Our horizontal band saw C70 is made especially for cutting ice on slabs by a fast method, in 15 minutes the big block completely turns into 15-20 slabs for cutting. Slabs are ideally equal and with minimal ice loss. This saw requires – a place of 2×2 meters (7×7 feet) minimum, a powerful connection for 3 or 1 phase, and 3.5 kW / 25 Amp. The block can be cut both from the ground with the subsequent rise, and on the lifting cart (ours or another).

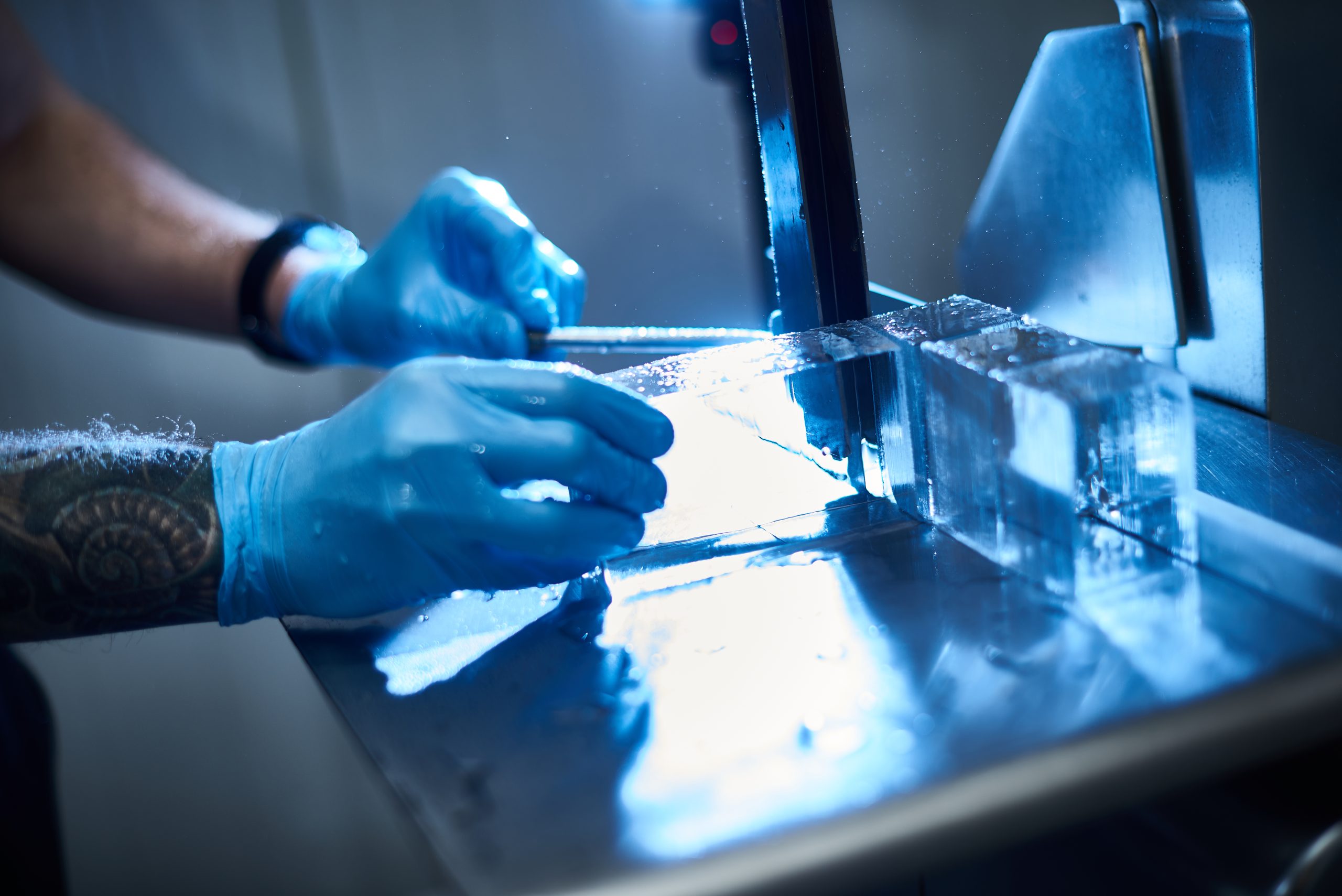

Cutting Ice Slabs into Cubes:

Once you have got flat ice slabs from a large block – you can proceed to cut it into cubes 5×5 cm (2×2 inches), 4×11 cm (1.5×4 inches), etc., for this we use meat stainless steel saws for butchers.. The main brands are Kolbe, Bizerba, Biro, MADO, Brice and others. You can buy a new one or similar/used in your country.

The process looks like this.

After cutting the ice into cubes, you need to store them in a suitable freezer – walk-in, chest, or vertical. Depending on the volume of ice you are going to produce you need to choose a suitable place for storage.

Additional Equipment:

At all stages, there are certain additional spare parts for each unit of ice equipment types – liner bags, stainless steel ice holders, circulation pumps, blades, etc.

You will receive all this with the equipment, but you can order additional quantities from us later.

Minimum Setup for Quality Work:

For a quality start, we recommend our P150/P300 block machine + saw for cutting C70 + electric hoist + till cart to move + a certain number of presses.

Warranty and Shipping costs:

The warranty information is available in the catalog and, like all manufacturers, we offer a 1-year warranty for equipment components. The shipping cost is calculated based on the number of equipment units required.

Additional Equipment:

At all stages, there are certain additional spare parts for each unit of equipment – liner bags, stainless steel ice holders, circulation pumps, blades, etc.

You will receive all this with the different ісe equipment types, but you can order additional quantities from us later.

Minimum Setup for Quality Work:

For a quality start, we recommend our P150/P300 block machine + saw for cutting C70 + electric hoist + till cart to move + a certain number of presses.

Warranty and Shipping costs:

The warranty information is available in the catalog and, like all manufacturers, we offer a 1-year warranty for equipment components. The shipping cost is calculated based on the number of equipment units required.

FAQ

What equipment do I need to make ice?

The type of ice-making equipment you need depends on your specific needs.To make ice efficiently, you'll need a few key pieces of equipment, and BF Tech offers top-of-the-line options to meet your needs: - Ice Block Machines (P30, P150, P300) - Hoist for Ice Block Removal - Till Cart - Bandsaw C70 - Additional Equipment

Where can I buy professional ice equipment?

Professional ice equipment types of machines can be purchased at kitchen and restaurant supply stores. They can also be obtained directly from manufacturers who specialize in this type of product. Researching different companies that sell these machines is recommended before making any purchases.

Who needs an ice block maker?

If your business often requires large amounts of ice, investing in an ice block maker will help you tremendously. Industries like fishing, shipping, event catering, etc., rely heavily on large ice blocks for cooling. Likewise, restaurants with high outputs of cold beverages or that require chilling large containers will benefit from having this machine on site.

Which ice block maker is better to choose?

In order to decide which ice maker you should choose, we advise you first to understand how many cubes you want to produce and sell during the month/year, and based on this, our team will be able to advise you on the best choice. If your idea is to open an ice production, then the minimum setup for quality work will look like this - we recommend our P150/P300 block machine + saw for cutting C70 + electric hoist + till cart + a certain number of presses.