Mastering the Lift: An In-Depth Guide to Different Types of Hoists

Hoists Overview

In the world of material handling and lifting, hoists play a vital role.

What’s that?

A hoist is a device used for lifting or lowering a load using a drum or lift-wheel around which rope or chain wraps. It may be manually operated, electrically, or pneumatically driven and may use chain, fiber, or wire rope as its lifting medium.

Understanding the different types of hoists and their applications is crucial for selecting the right equipment for the job.

In this article, we will explore the different types of hoists, its unique features, advantages, and variety of applications.

Keep on reading to find out more.

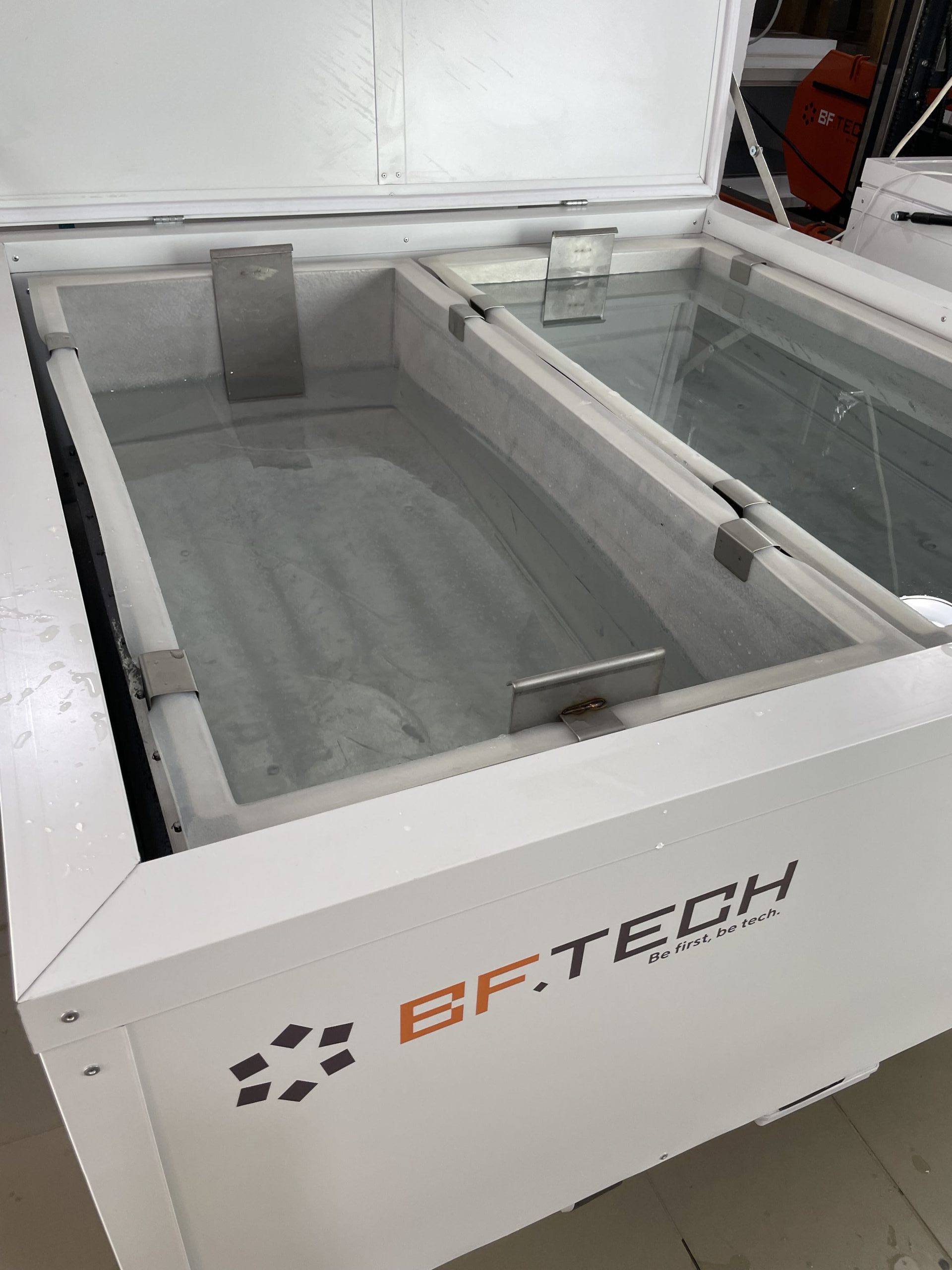

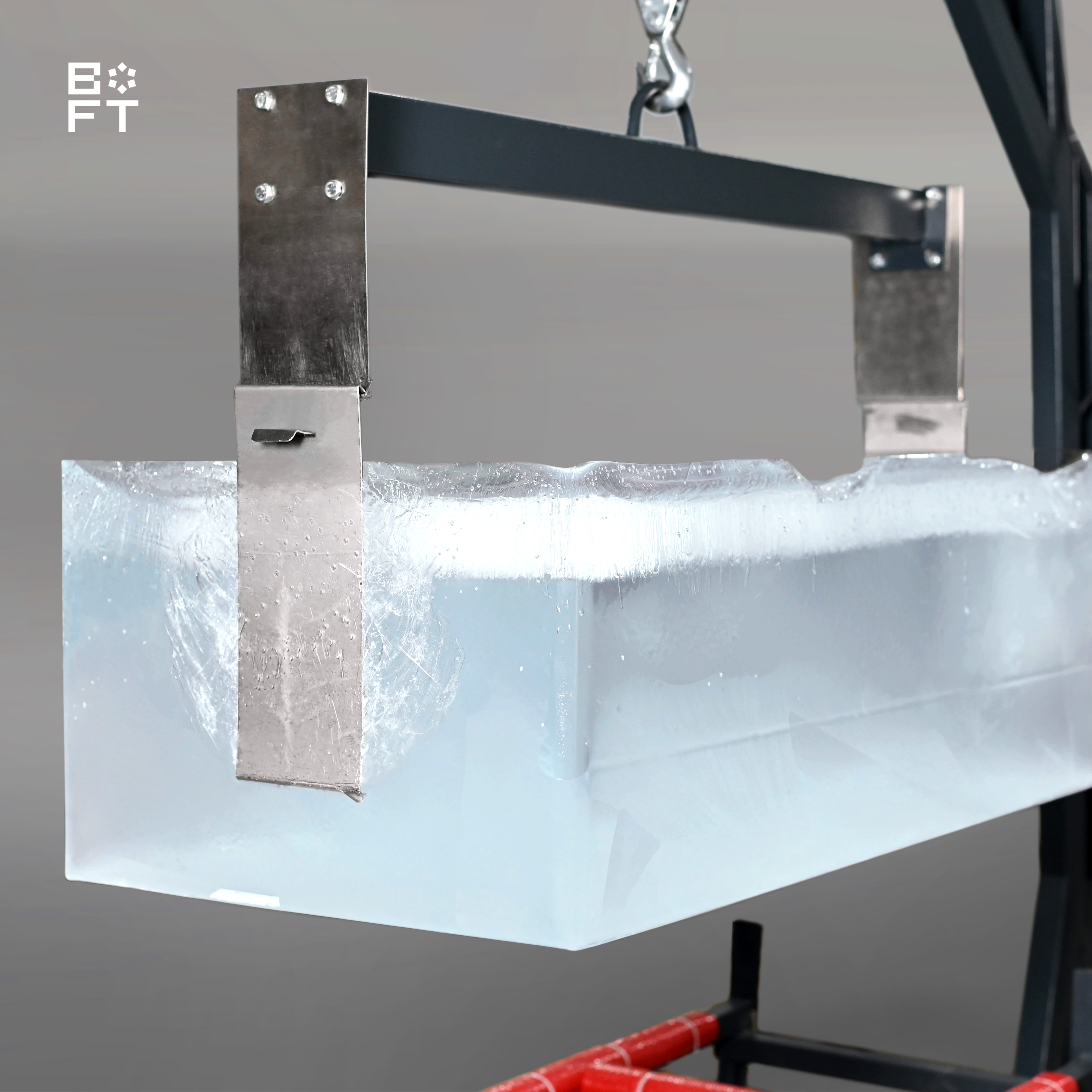

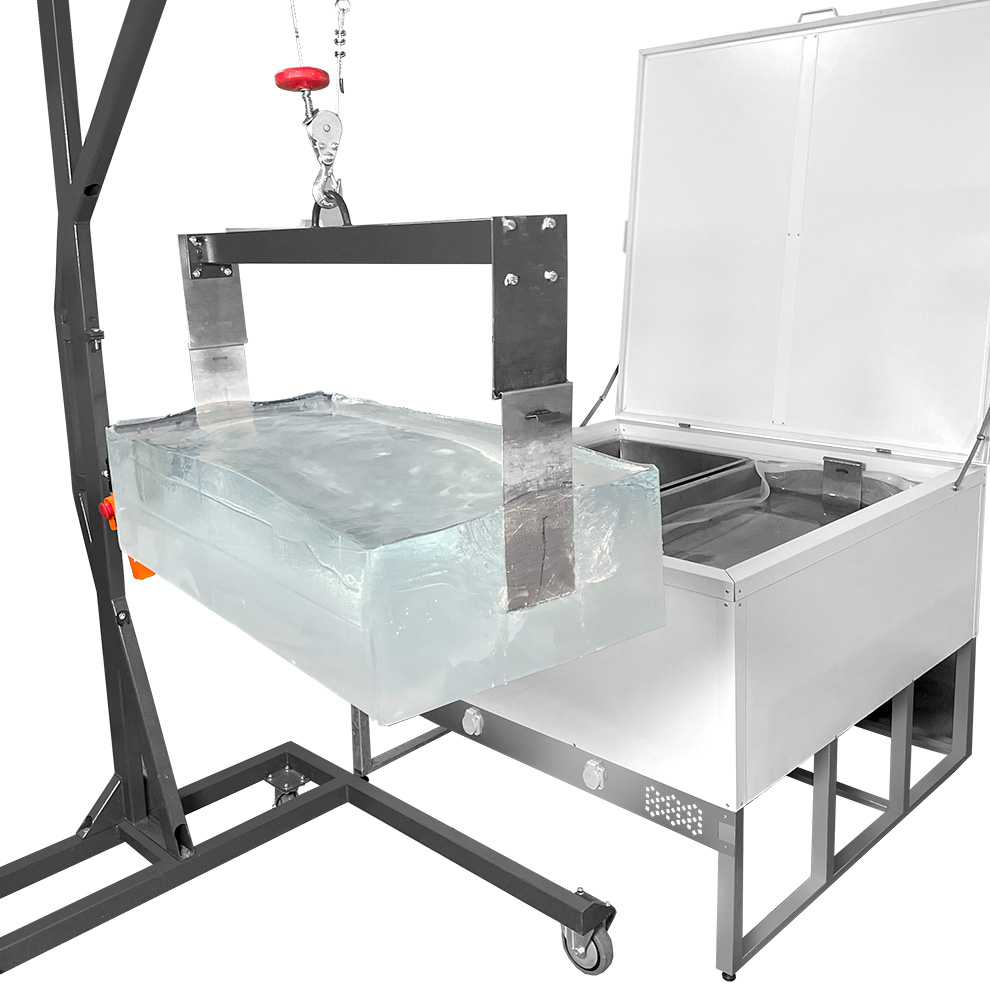

Ice Block Hoists: Specialized Equipment for Cold Environments

Ice block hoists are engineered to handle the unique challenges posed by large, slippery ice blocks, ensuring safe and efficient operation in dangerous environments.

Here are the most popular types of hoisting equipment for ice:

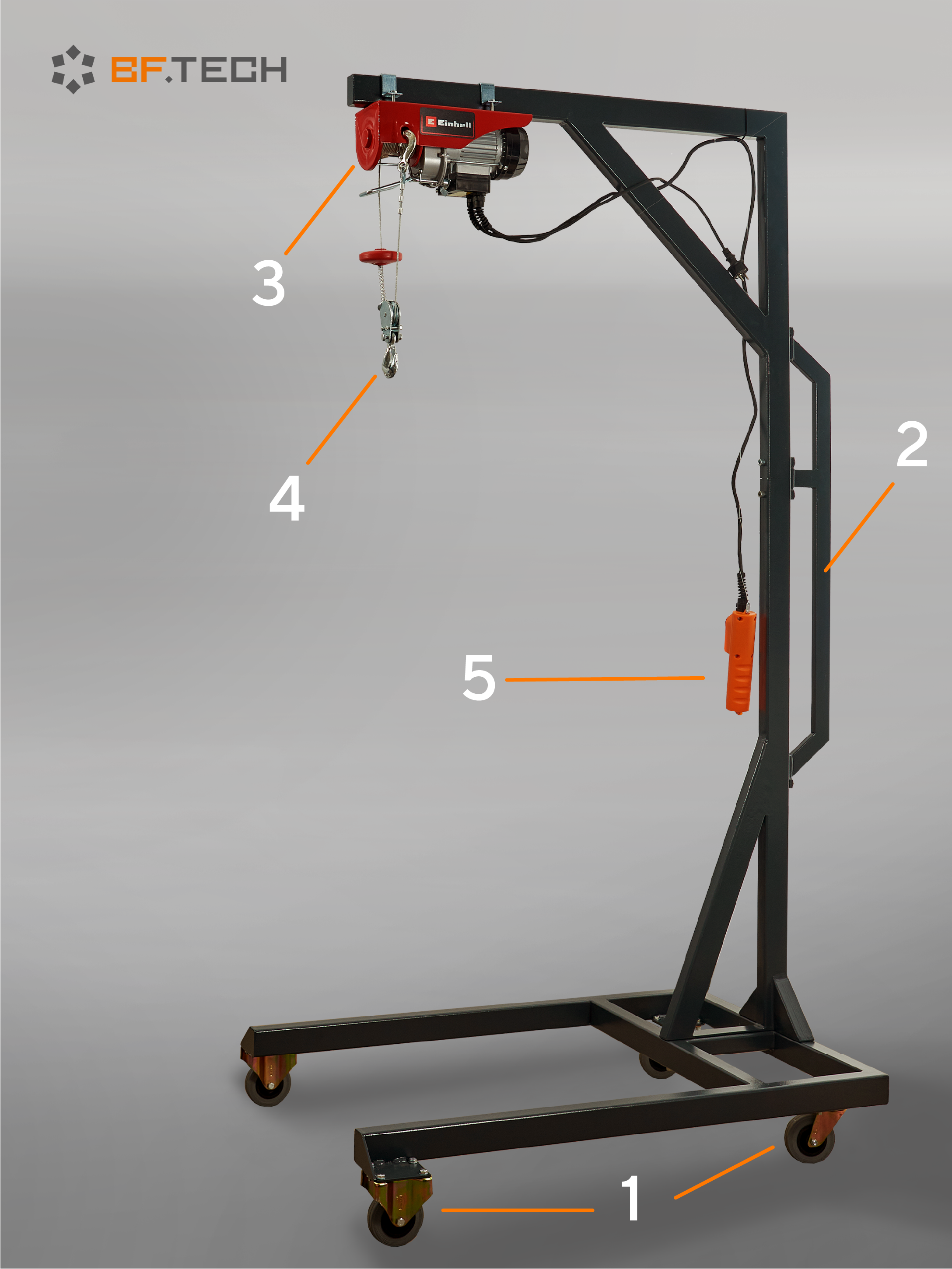

Electric Ice Block Hoists

Electric ice block hoists are powered by electricity, designed for heavy ice blocks, typically used in industrial settings for high-volume ice machine lift operations.

Advantages:

- High lifting capacity for large ice blocks

- Efficient and quick, ideal for frequent use

- Minimal physical effort required from the operator

Disadvantages:

- Requires access to an electrical power source

- Higher initial cost compared to manual hoists

- Less portable, mainly suitable for fixed locations

Manual Ice Block Hoists

Operated by hand, ideal for smaller-scale operations or areas without electrical power, more portable and simpler in design.

Advantages:

- Independent of electricity, offering greater portability

- Lower cost and simpler maintenance

- Useful in remote or outdoor locations

Disadvantages:

- More physical effort needed from the user

- Slower operation and lower lifting capacity

- Not suitable for continuous, heavy-duty lifting

Portable Ice Block Hoists

Designed for mobility, can be either electric or manual, suitable for operations where the hoist needs to be frequently moved.

Advantages:

- Easy to transport and set up in various locations

- Flexible in terms of power source (electric or manual)

- Adaptable to different operational needs and load capacity

Disadvantages:

- Potentially lower lifting capacity

- Stability issues if not properly secured

- Increased wear and tear due to movement

Stationary Ice Block Hoists

Fixed in one location, typically used for consistent operations in industrial environments, built for durability and higher lifting capacities.

Advantages:

- Suitable for heavy and regular lifting tasks

- Higher lifting capacity and robust construction

- Ideal for a dedicated lifting station

Disadvantages:

- No mobility, limited to one location

- Requires dedicated space for installation

- Less flexibility for varying tasks

Manual Hoists: Lever and Hand Chain

Manual hoists are appreciated for their simplicity, reliability, and ease of use, especially in settings where electricity is unavailable or in tasks requiring precise control.

Lever hoists are known for their portability and are commonly used for lifting, pulling, and positioning heavy loads. They operate through a lever mechanism, allowing for fine control.

Hand chain hoists, on the other hand, are operated by pulling on a chain loop. Such chain manual hoists are typically used for vertical lifting and are a staple in many workshops and industrial settings.

Electric Hoists: Power and Efficiency

Electric hoists are driven by electric motors, offering a blend of strength, speed, and ease of use that is unmatched by manual alternatives. They are particularly well-suited for repetitive lifting tasks in industrial environments.

Electric hoists come in various designs, including wire rope and electric chain hoists models, each tailored to specific lifting needs. They are often controlled via a remote or a control pendant, allowing the operator to maintain a safe distance during lifting operations.

Chain Hoists: Flexible and Strong

Chain hoists are a vital component in the lifting equipment arsenal, known for their robustness and versatility. These hoists use metal chains as their lifting medium and are favored in numerous industrial applications for their durability and reliability.

Chain hoists come in both manual and powered variants, catering to a wide range of lifting requirements. The manual chain hoists are often preferred for smaller-scale operations or in environments where electricity is not available. Powered load chain hoists, including electric and pneumatic types of lifting devices, are used for more demanding tasks, where they excel in lifting heavier loads with ease.

Pneumatic Hoists

Components of a Hoist

Pneumatic hoists, powered by compressed air or pneumatic power, are a unique and valuable tool in the lifting equipment landscape. Such hydraulic hoists are particularly favored in environments where safety and cleanliness are paramount, such as in chemical, pharmaceutical, or food processing industries.

The primary characteristic of air hoists is their use of air power, which eliminates the risk of sparks and makes them an ideal choice in explosive or flammable environments. This feature also contributes to their durability, as they are less susceptible to damage from dust, dirt, and moisture compared to electric hoists.

Air-powered hoists are known for their variable speed control, which allows for precise handling of loads. This is especially beneficial in applications where delicate or precise positioning is required.

A hoist is a complex assembly of parts working together to ensure safe and efficient operation. Understanding the components of a hoist is crucial for proper use, regular maintenance, and troubleshooting.

Here are some key components commonly found in most hoists:

- Motor

The motor is the heart of a powered hoist, whether electric or pneumatic. It provides the necessary power to lift and lower loads.

- Lifting Medium

This can be a chain or wire rope, depending on the type of hoist. It’s the part that actually lifts and supports the load.

- Control Mechanism

This includes pendants or remote controls for operating the hoist. In manual hoists, this would be the hand chain or lever.

- Brake System

A critical safety mechanism, the brake system ensures the hoist can hold and lower loads safely and prevent unintentional movement.

- Gearbox

In powered hoists, the gearbox is essential for transferring power from the motor to the lifting medium, often reducing speed to increase lifting power.

- Limit Switches

These switches are safety features that prevent over-travel of the hoist, both in the upward and downward directions.

- Load Hook

The component that actually attaches to the load, often equipped with a safety latch to prevent dislodgement of the load.

How to Choose The Right Lifting Hoist?

Conclusion

Choosing the types of hoists for your specific needs is crucial for both the efficiency and safety of your operations.

Here are some key factors to consider when selecting a hoist for a range of industries:

Determine the Load

Assess the weight and dimensions of the items you’ll be lifting. Ensure the hoist you choose has a capacity that exceeds your maximum load.

Consider the Environment

The environment where the hoist will be used can greatly influence the type you need. For example, pneumatic hoists are ideal for explosive environments, while electric hoists are better suited for standard industrial settings.

Frequency of Use

Consider how often the hoist will be used for better equipment life. For heavy, daily use, an electric or pneumatic hoist might be more appropriate, whereas for occasional use, a manual hoist could suffice.

Lifting Height and Speed

Determine the required lift heights, lift capacity, and desired lift speed. Different hoists offer varying speeds and maximum lifting heights.

Power Source

Ensure that the power source required for the hoist is available in your facility. Electric hoists need a power supply, while pneumatic hoists require a compressed air source.

The world of hoists is diverse and complex, with each type offering unique benefits suited to different applications. From the simplicity and reliability of manual hoists to the power and efficiency of electric and pneumatic models, understanding the various hoist sling types is key to making an informed decision for your lifting needs.

The choice of the right hoist impacts not only the efficiency of your operations but also the safety of your workforce. It’s a balance of understanding your specific requirements, the nature of the load, the environment of operation, and the frequency of use. Whether it’s for lifting ice blocks in cold environments or handling heavy materials in an industrial setting, there is a hoist designed to meet those challenges.

FAQ

How many hoist types exist?

There are several types of hoist, each designed for specific lifting needs. The main types of lifting equipment include manual hoists (like lever and hand chain hoists), electric hoists, pneumatic hoists, and specialized hoists such as ice block hoists. Within these categories, there are further variations based on lifting capacity, speed, and design.

What's the most used type of hoist?

The most common types of hoists used are manual chain hoists, electric wire rope and chain hoists, and pneumatic hoists. Their popularity stems from their versatility, efficiency, and suitability for a wide range of applications.

What are the different types of chain hoists?

Chain hoists are generally categorized into three hoist types: manual chain hoists, electric chain hoists, and pneumatic chain hoists. Manual chain hoists are operated by hand, electric chain hoists use electric power for operation, and pneumatic chain hoists are powered by compressed air.

Which hoist type is the best?

The "best" types of lifting equipment depends on the specific requirements of the task, including the weight capacities, the environment, lifting mechanism, and the frequency of use. For heavy, regular lifting in an industrial setting, electric hoist types are often preferred. For hazardous environments, pneumatic hoists are ideal, while manual hoists are suitable for lighter loads and less frequent lifting.