Comparing Top Bandsaw Brands for Ice Cutting: Which Stands Out?

Our custom bandsaw guide provides an insightful exploration of bandsaw technology, tailored for those interested in the art of ice sculpting and ice tools or the functional requirements of cutting ice.

We navigate through the latest innovations in bandsaws, highlighting what sets them apart and select which one is better for ice cutting for events.

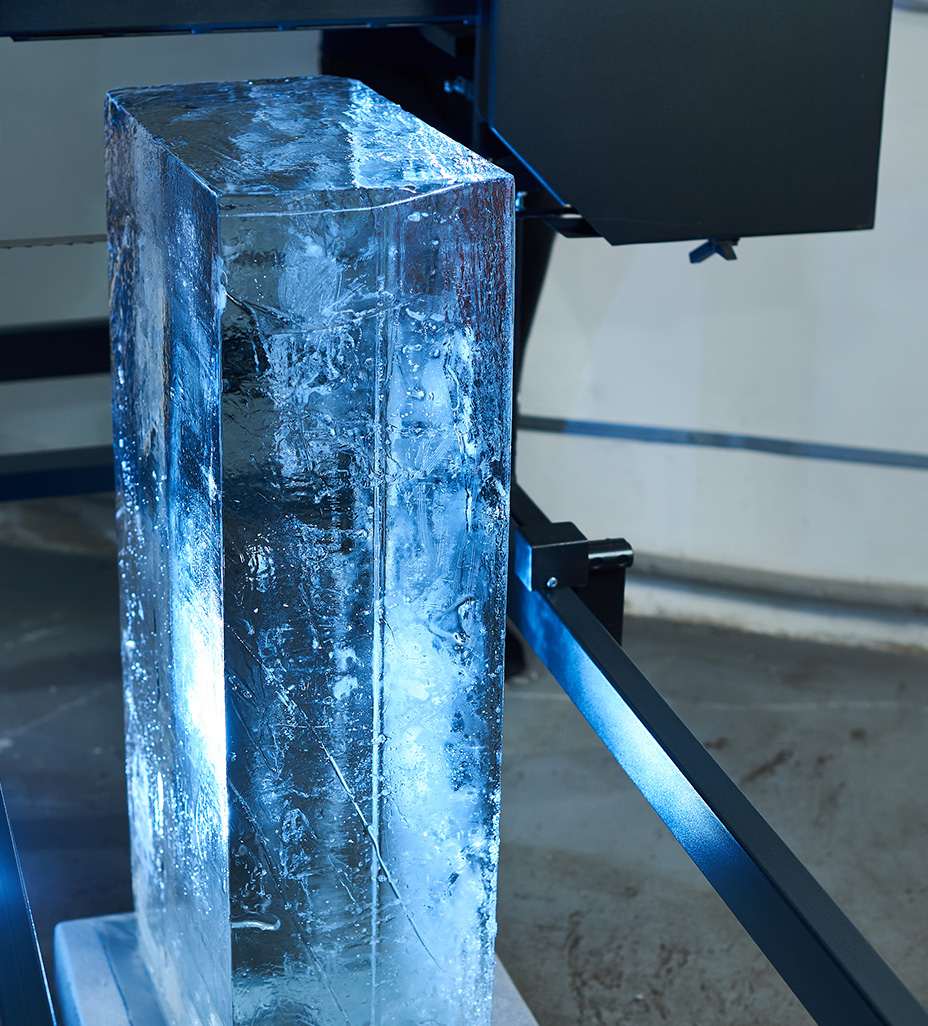

Bandsaw Technology for Ice Cutting

Ice Cutting Bandsaw Brands: A Comparative Analysis

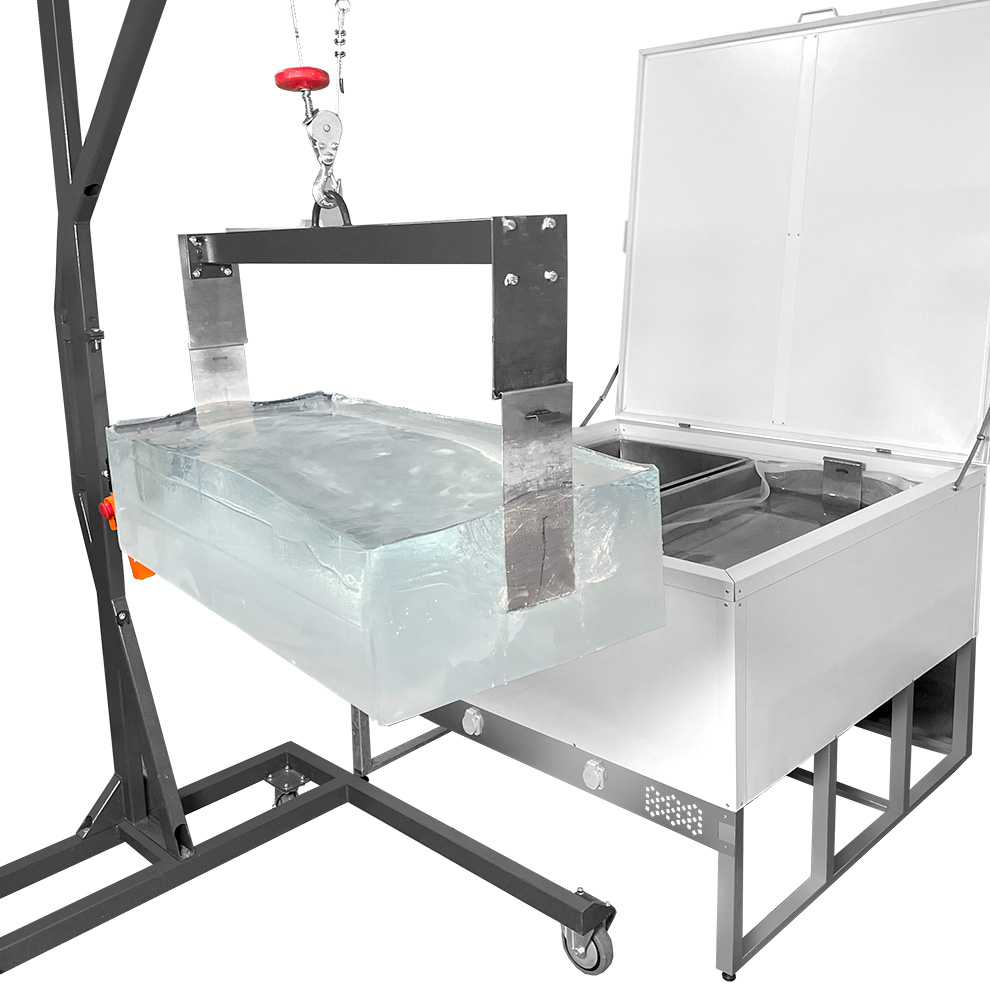

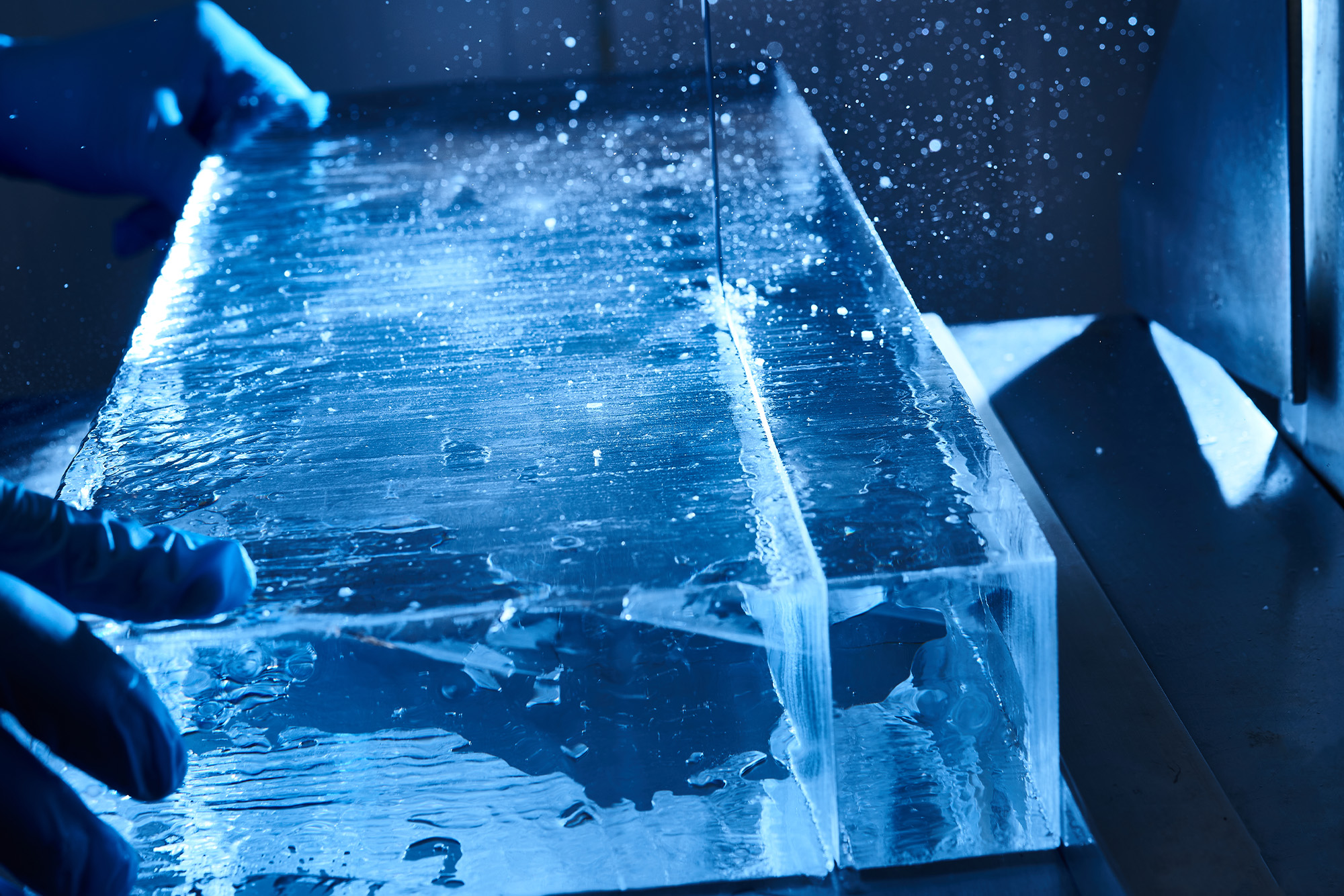

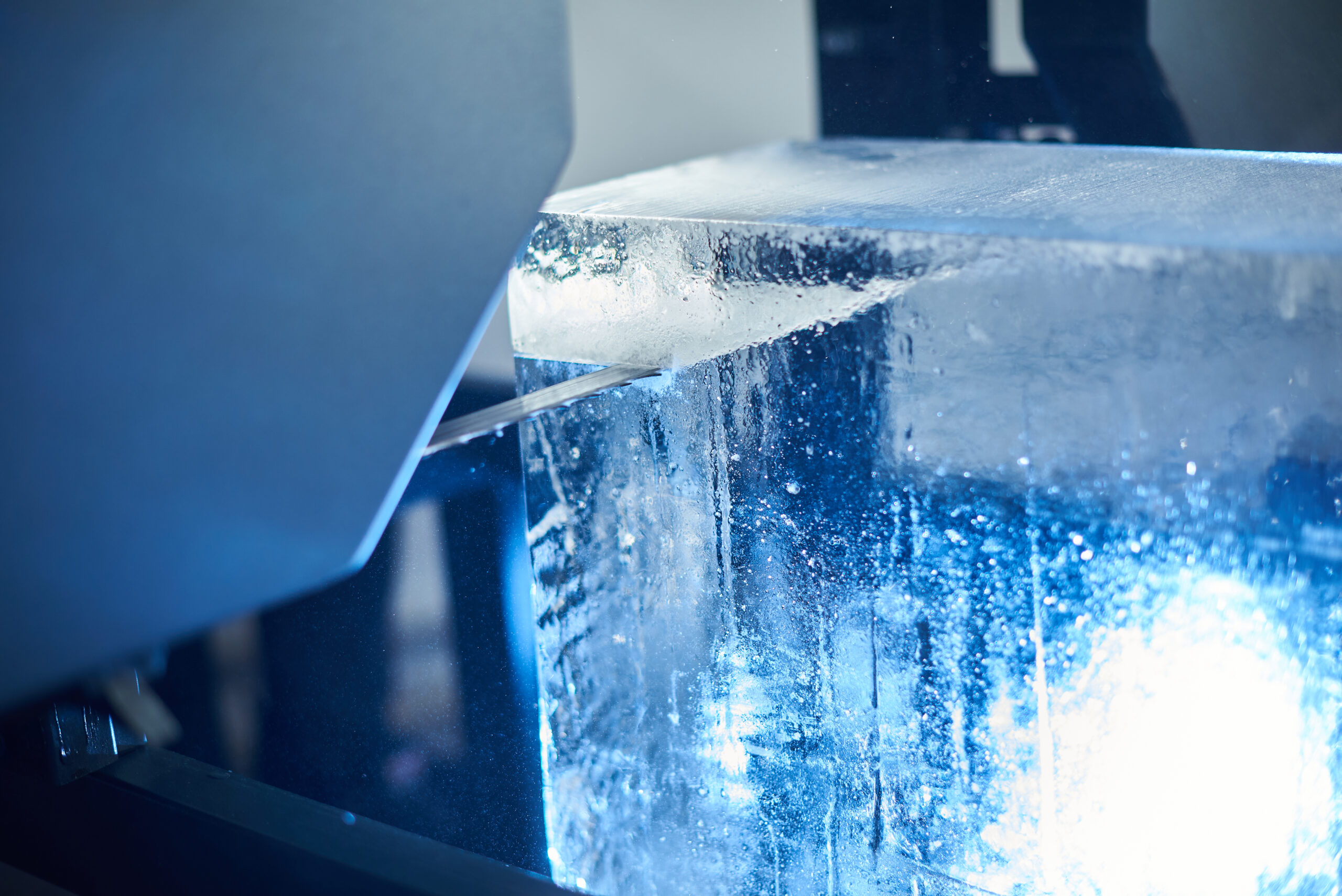

Bandsaws designed for cutting ice on bandsaws have evolved significantly, distinguishing themselves from traditional models. These specialized bandsaws feature blades made from corrosion-resistant materials like stainless steel, tailored specifically for smoothly cutting through ice balls, ice share, or ice slabs without causing cracks or shattering.

Key to their functionality is the motor and power transmission, engineered to provide consistent force and speed essential for ice cutting bandsaw operations. This ensures smooth, precise cuts even in cold conditions.

In the market of bandsaw ice cutting, certain brands have made a name for themselves. In this article, we will talk about several of them:

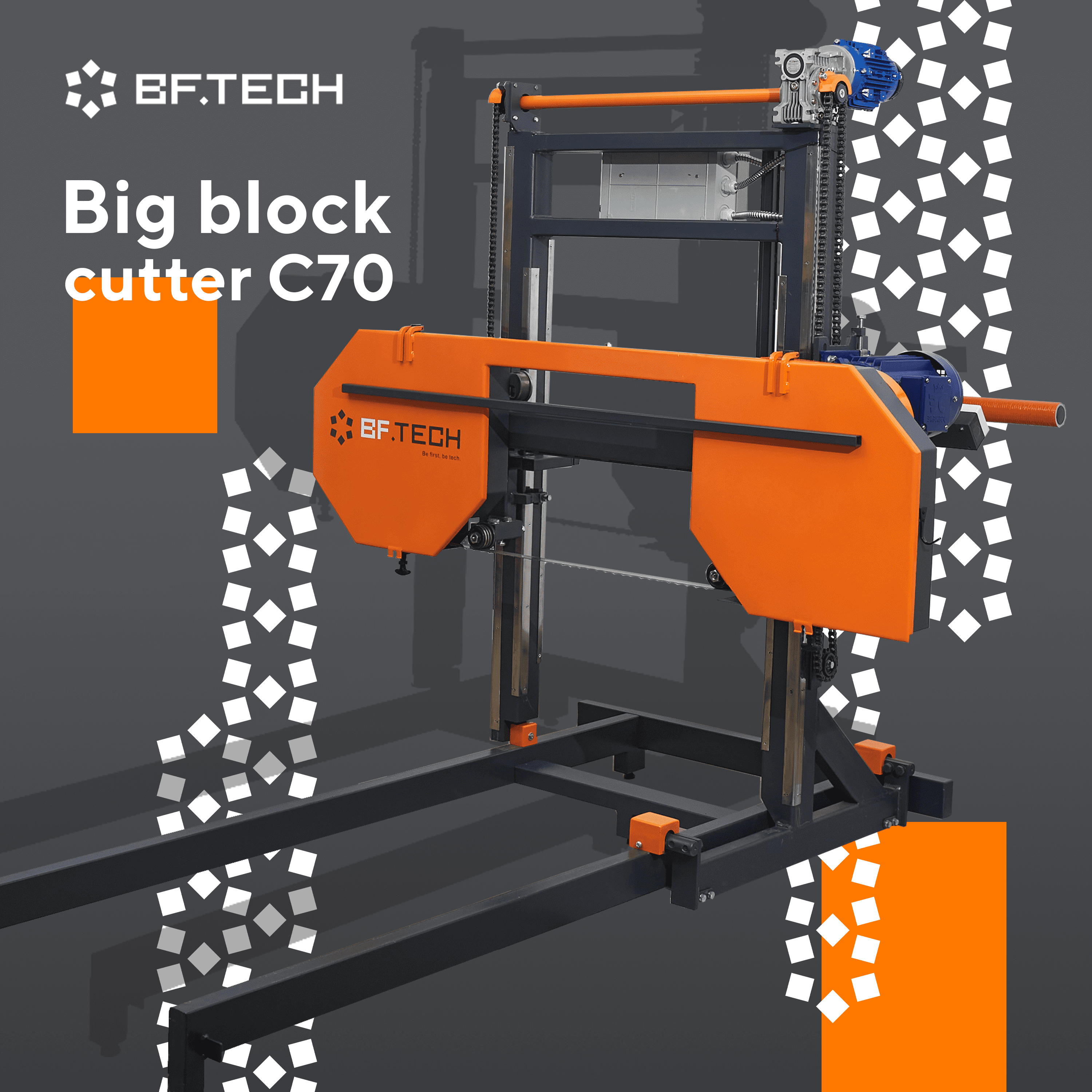

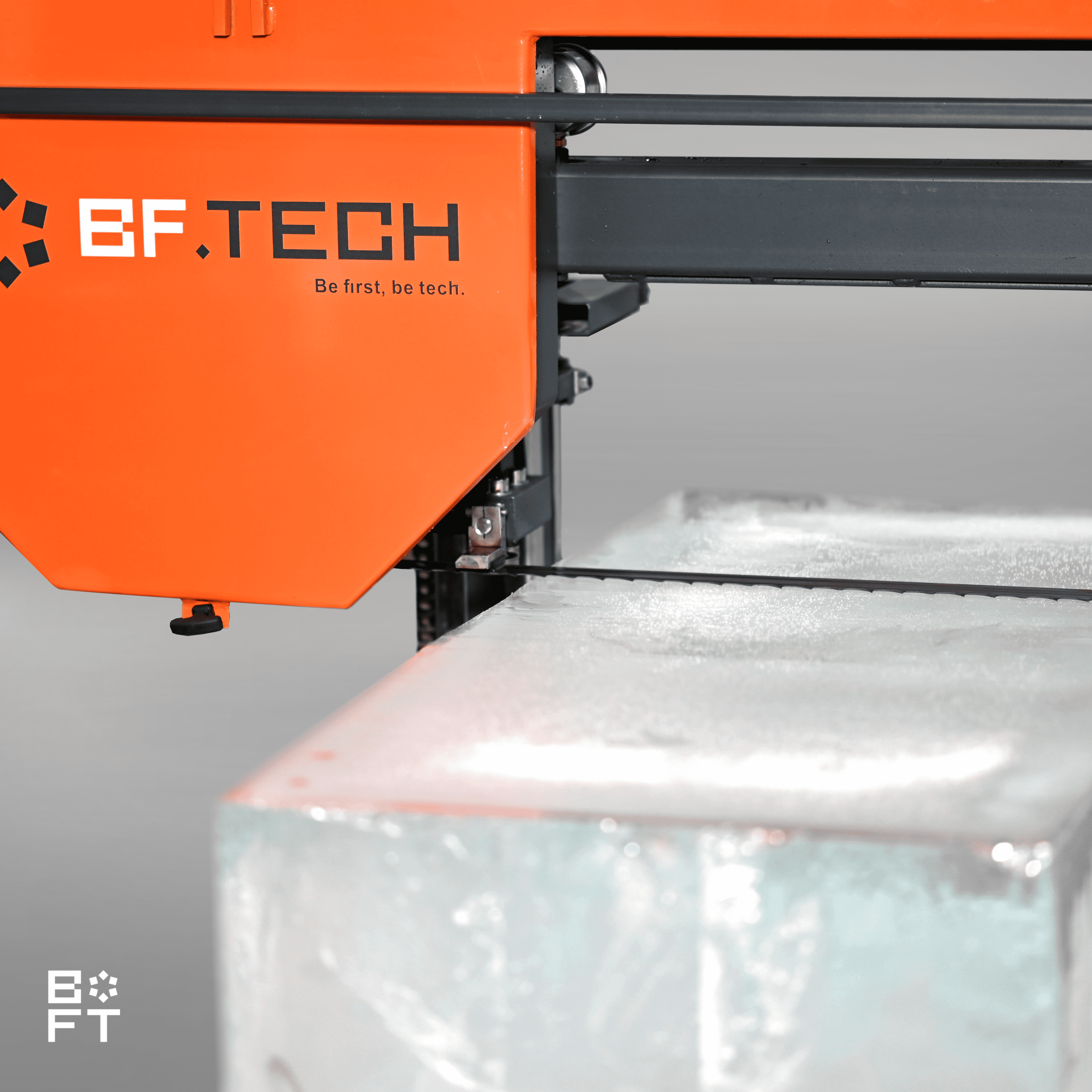

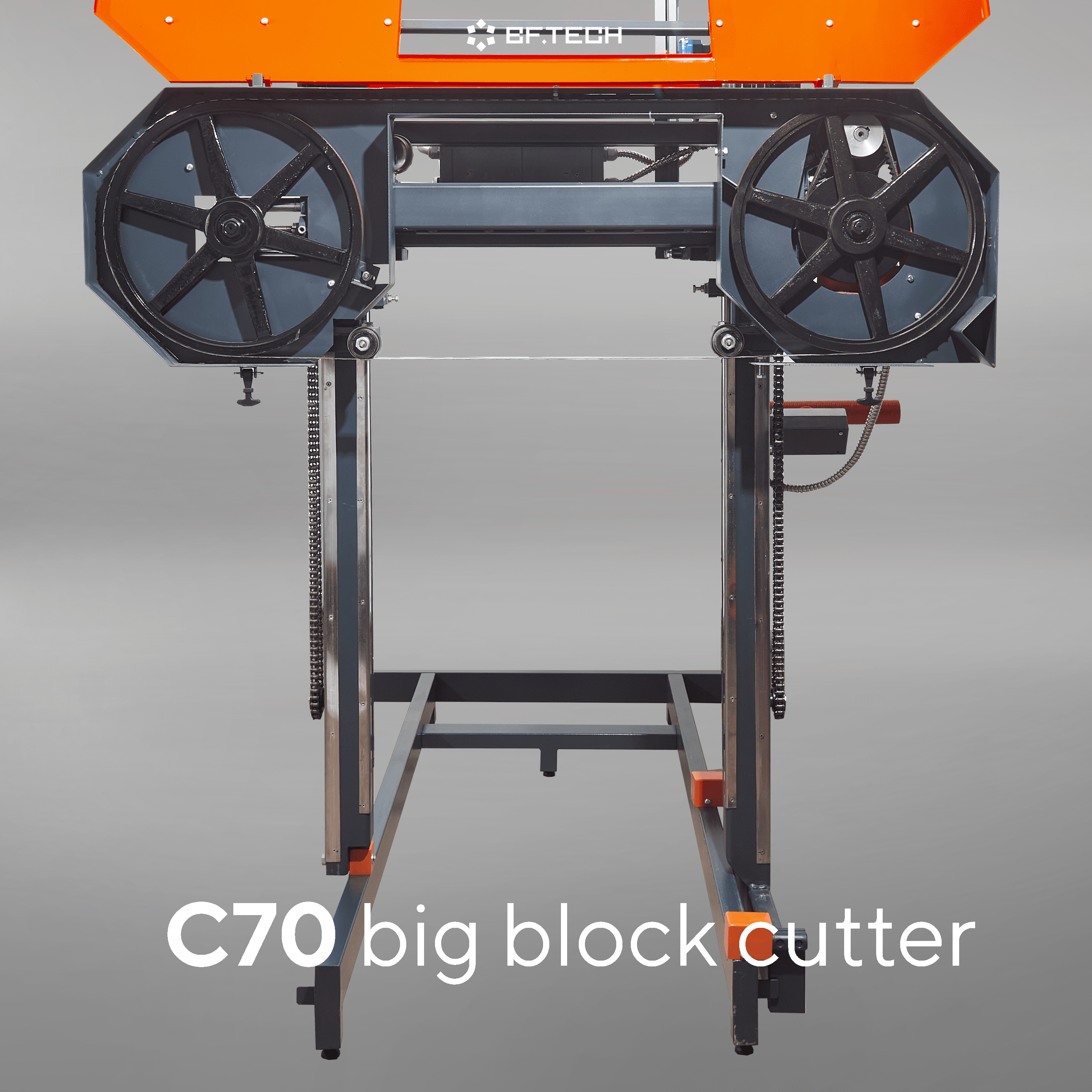

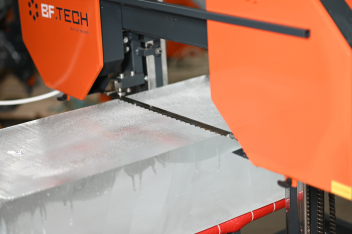

BF TECH

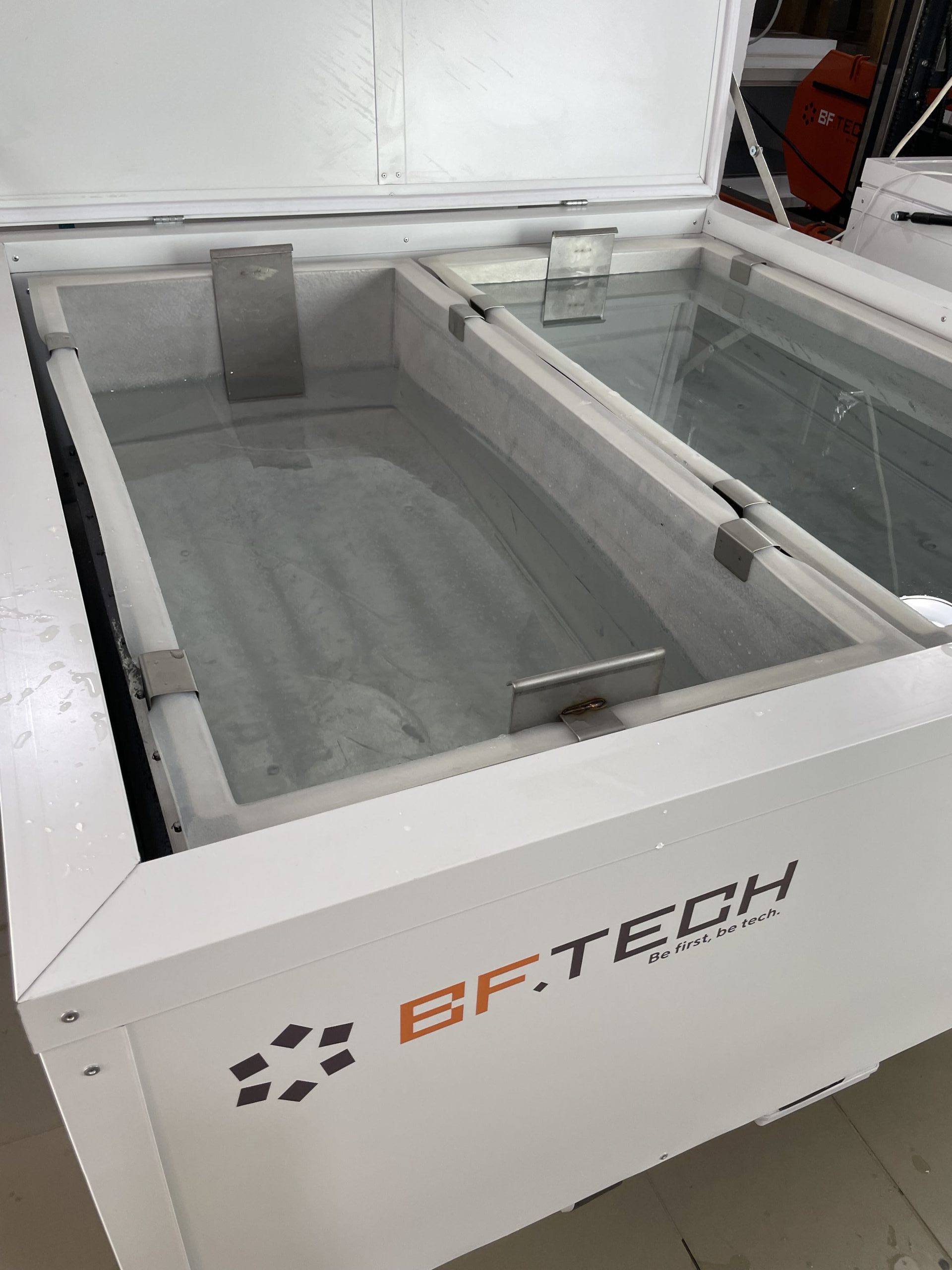

Known for its modified ice band saws, BF TECH offers electric models designed for fast and efficient ice cutting into slabs and cubes. Their bandsaws are fully electric with remote control, compact in format, and user-friendly. BF TECH’s saws are adaptable to global voltage systems, emphasizing safety, and are operable by a single person.

Ice Sculpting Tools

This brand specializes in precision cutting of ice with its Ice Mill Band Saw. The tool is favored for its accuracy in shaping ice blocks and intricate designs. It’s ideal for professionals seeking precision in ice sculptures.

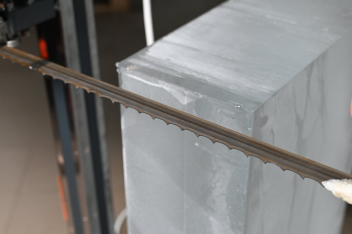

Saws UK

As a leading supplier of customized cutting machines in the UK, Saws UK has developed bespoke bandsaw machines tailored for cutting ice blocks. Their utilization of carbide-tipped blades known for longevity, and a linear guide for ease of use, positions them as efficient and durable ice cutting solutions.

Key Features to Look For in Ice Cutting Bandsaws

When selecting a bandsaw for ice, several key features are crucial for optimal performance and safety:

1. Blade Quality

The blade is the heart of the ice cutting bandsaw. Look for blades made from high-grade, corrosion-resistant materials like aluminium-cutting bandsaws, with tooth designs optimized for smooth cutting through ice. This minimizes the risk of shattering or cracking the ice.

2. Motor Strength & Efficiency

A powerful and efficient motor ensures consistent cutting speed and force, essential for cutting ice with a bandsaw. It should be capable of maintaining performance in cold conditions without overheating.

3. Ease of Use

The bandsaw should have user-friendly controls and an ergonomic design. This not only enhances the comfort of the operator but also improves the precision of the cuts.

4. Safety Features

Safety is paramount in bandsaw ice cutting. Features like emergency stop buttons, blade guards, and anti-vibration systems contribute to safer operation, particularly important for beginners or in educational settings.

5. Durability & Material

The construction of the bandsaw should be robust, with materials that can withstand low temperatures and moisture without warping or rusting. This ensures longevity and consistent performance.

Durability and Performance: Brands that Lead the Way

In the field of ice cutting bandsaws, durability and performance are key differentiators among brands.

BF TECH is acclaimed for its durable design and consistent performance, especially in cutting large blocks of ice. Their saws are designed to withstand the rigors of ice cutting, making them a reliable choice for frequent use.

Saws UK stands out for their customized cutting solutions. Known for their carbide-tipped blades which ensure longevity, and their user-friendly linear guides, they offer bandsaws that are both efficient and durable, ideal for varied ice cutting requirements.

Ice Sculpting Tools, with their Ice Mill Band Saw, specializes in precision. These tools are favored for detailed and intricate ice work, making them a go-to for artists and professionals in ice sculpting who demand accuracy and finesse in their creations.

Efficiency in Ice Cutting: Which Bandsaw Brands Excel?

In the niche market of bandsaw ice cutting, efficiency is a crucial factor. Brands that stand out for their efficiency and innovation include BF TECH and Saws UK. They are known for their modified ice band saws and bespoke bandsaw machines, respectively. Ice Sculpting Tools is also notable for its Ice Mill Band Saw, designed for precision ice cutting. Ideal for artists and professionals in ice sculpting, their tools are celebrated for their ability to create intricate designs and detailed work with ease and efficiency.

User Experience and Ease of Use

A good user experience in selecting a bandsaw for ice includes simple and clear controls, comfortable handling, and safety features like emergency stops and blade guards. These aspects contribute to ease of operation and safety, essential for both beginners and experienced users.

Price Comparison: Balancing Quality and Affordability

When comparing bandsaws for ice cutting, price is a critical factor. Brands vary in how they balance cost with quality:

Premium Brands

These offer advanced features like superior blade quality and innovative technology, but at a higher price point. Ideal for professionals needing high precision and durability.

Mid-Range Brands

Targeting a balance between quality and cost, these bandsaws offer reliable performance for regular use without the premium price tag.

Budget-Friendly Options

For occasional users or those with limited needs, budget brands provide basic functionality at a lower cost, though they may lack advanced features, lots of advantages of ice cutting, and robustness.

Safety Features in Top Bandsaw Brands

Safety is a top priority in bandsaw ice cutting. Common safety features in top brands include emergency stop buttons, blade guards, anti-vibration systems, and cooling systems to prevent overheating. These features are essential in minimizing risks during ice cutting, making the bandsaws safer for users of all skill levels.

Innovations and Technological Advancements

The ice cutting bandsaw market has seen significant technological advancements. These include digital controls for enhanced precision in cutting patterns and speeds, advanced blade technology for more efficient and longer-lasting cuts, and automated systems for consistent cuts with minimal manual intervention. Material innovations have also played a role, with the use of more durable, cold-resistant materials for longevity.

Brand Reliability and Customer Support

When choosing a bandsaw for ice, brand reliability and quality of customer support are important considerations. Brands with a reputation for durable and consistent performance are preferred. Equally important is the availability of responsive and knowledgeable customer support, invaluable for troubleshooting, maintenance advice, and accessing spare parts. A combination of reliability and strong customer support ensures a smoother, more dependable experience in ice cutting.

Comparing Warranty and Service Agreements

Examining the warranty and service agreements of different bandsaw brands is crucial when considering a purchase. BF TECH and Saws UK, for example, offer warranties and comprehensive service agreements, reflecting their commitment to quality and customer satisfaction.

Expert Reviews: What Professionals Say

Professionals in the field recognize Saws UK, BF TECH, and Ice Sculpting Tools for their durability, performance, and precision in ice cutting. Saws UK is known for their durable and efficient bandsaws with a 10-year warranty. BF TECH specializes in modified ice band saws with a 12-month guarantee, acclaimed for their durability and performance in cutting large ice blocks. Ice Sculpting Tools offers the precision-oriented Ice Mill Band Saw suitable for professional ice sculptors.

Customer Feedback and Ratings

Customer satisfaction and feedback highlight the efficiency, durability, ease of use, safety, and performance of bandsaws from these top brands. Saws UK consistently receives high marks for customer satisfaction, while BF TECH’s bandsaws are noted for their ease of use and adaptability. Ice Sculpting Tools is highly regarded by professional ice sculptors for its precision in shaping ice blocks and intricate designs.

Bandsaw Blades for Ice Cutting: An Overview

The choice of blade is crucial in bandsaw ice cutting. Here’s an overview of the types of blades used and their features:

- Material

Blades for ice cutting are typically made from stainless steel or other rust-resistant materials. This ensures longevity and maintains sharp metal even in cold, wet conditions.

- Tooth design

The design of the teeth on the blade significantly impacts the quality of the cut. Blades with finer teeth are preferred for detailed and intricate cutting, while coarser teeth are better for larger, rougher cuts.

- Width and thickness

The width and thickness of the blade affect its flexibility and strength. Narrower blades are ideal for making curved or intricate cuts, whereas thicker blades offer more stability for straight cuts.

- Tension and alignment

Proper blade tension and alignment are essential for efficient cutting. Misaligned or improperly tensioned blades can lead to uneven cuts or increased wear on the bandsaw.

Maintenance and Care Tips for Bandsaws

Proper maintenance and care are key to extending the life and efficiency of a bandsaw for ice cutting. Here are some essential tips:

1. Regular cleaning

After each use, clean the bandsaw to remove ice residue and moisture. This prevents rust and maintains blade sharpness.

2. Blade inspection and replacement

Regularly inspect the blade for wear or damage. Replace it as needed to ensure consistent cutting quality and safety.

3. Lubrication

Regularly lubricate moving parts to reduce friction and prevent wear. Use lubricants suitable for low temperatures and food-safe if applicable.

4. Tension adjustment

Check and adjust the blade tension regularly. Proper tension ensures efficient cutting and prolongs blade life.

5. Storage

Store the bandsaw in a dry, cool place to prevent corrosion and other damage due to moisture and temperature fluctuations.

6. Routine check-ups

Schedule routine maintenance check-ups to identify and address potential issues before they become major problems.

The Future of Ice Cutting Bandsaws

The future of ice cutting bandsaws is shaping up to be an exciting blend of technology and innovation. We’re likely to see increased automation in bandsaw operations, enhancing precision while reducing manual efforts. Blade technology is expected to advance and become cutting-edge, with new materials and designs that allow for more efficient, durable, and intricate cuts. There’s a clear trend towards eco-friendly innovations, with bandsaws becoming more energy-efficient and using sustainable materials. Safety will continue to be a major focus, with the introduction of more sophisticated safety mechanisms to prevent accidents.

FAQs

Is cutting ice on a bandsaw safe?

Cutting ice on a bandsaw can be safe if you follow proper safety procedures and use a bandsaw designed for ice cutting, not some cheap meat bandsaw. Ensure that the bandsaw you use has the necessary safety features and that you are trained in its operation.

How long does a bandsaw blade last for ice?

The lifespan of a bandsaw blade for ice cutting varies depending on factors such as usage frequency, the type of ice being cut, and blade maintenance. Generally, with regular maintenance and careful use, a bandsaw blade can last for a significant amount of time before needing replacement.

Can I cut ice with a bandsaw?

Yes, you can cut ice with a bandsaw specifically designed for ice cutting. These bandsaws are equipped with features and blade designs optimized for cutting through ice efficiently and safely.

What should I consider when buying a bandsaw for ice cutting?

When purchasing a bandsaw for ice cutting, consider factors such as the blade type, blade width, safety features, ease of use, durability, and customer support. It's essential to choose a bandsaw that meets your specific ice cutting needs.

How do I maintain my bandsaw for optimal performance in ice cutting?

To maintain your bandsaw for optimal ice cutting performance, follow these tips: - Regularly clean the bandsaw to remove ice residue and moisture - Inspect the blade for wear and replace it as needed - Lubricate moving parts with suitable lubricants - Ensure proper blade tension and alignment - Store the bandsaw in a dry, cool place to prevent corrosion - Schedule routine maintenance check-ups to identify and address potential issues