How to cut an ice block? Best tool for cutting ice blocks

How to cut an ice block? Best tool for cutting ice blocks

High-quality ice is a vital ingredient to elevate customer service in restaurants, bars, hotels, and other service industries. However, some

companies get iced delivered in huge blocks, leaving them with the challenge of cutting through ice blocks. So how to cut block ice

without cracking it and losing in quality? The right device and techniques will do wonders for your business. Discover tool for cutting ice

that makes the process faster, cleaner, and more efficient from the top experts in the industry.

If you’re in search of an ice-cutting solution or looking for ways to optimize your techniques, read on!

The best way to cut block ice: Carving techniques

Cutting large blocks of ice requires the right tools and techniques to guarantee safety,

precision, and efficiency. The top 4 best carving methods you can consider are:

- Chainsaw: Spicifially designs chainsaw for ice is a powerful tool to cut through huge chunks and blocks of ice. Note that you can’t use any chainsaw you find for ice-carving purposes.

- Hotwire: With such a technique, you can melt through an ice block, creating a precise and clean cut. Hot wires are widely-used tools to carve unique shapes and designs.

- Ice pick: One of the most versatile tools used in ice carving is an ice pick. With such a sharp device, you can shape small and large ice blocks to create master-piece-like designs.

- Ice Chisel: As well as an ice pick, an ice chisel is a tool for sculping large blocks of crystal-clear ice. Such a technique is widely adopted in the ice art industry rather than the HoReCa business.

Whatever technique you choose, here are some tips on how best to cut a block of ice:

- Always start with a clean and level work surface;

- Use a sawhorse for steady support to hold the block in place;

- Wear appropriate safety gear, including eye protection and gloves;

- Keep the ice cool and reduce the melting process.

What is the best tool for cutting ice for a commercial company?

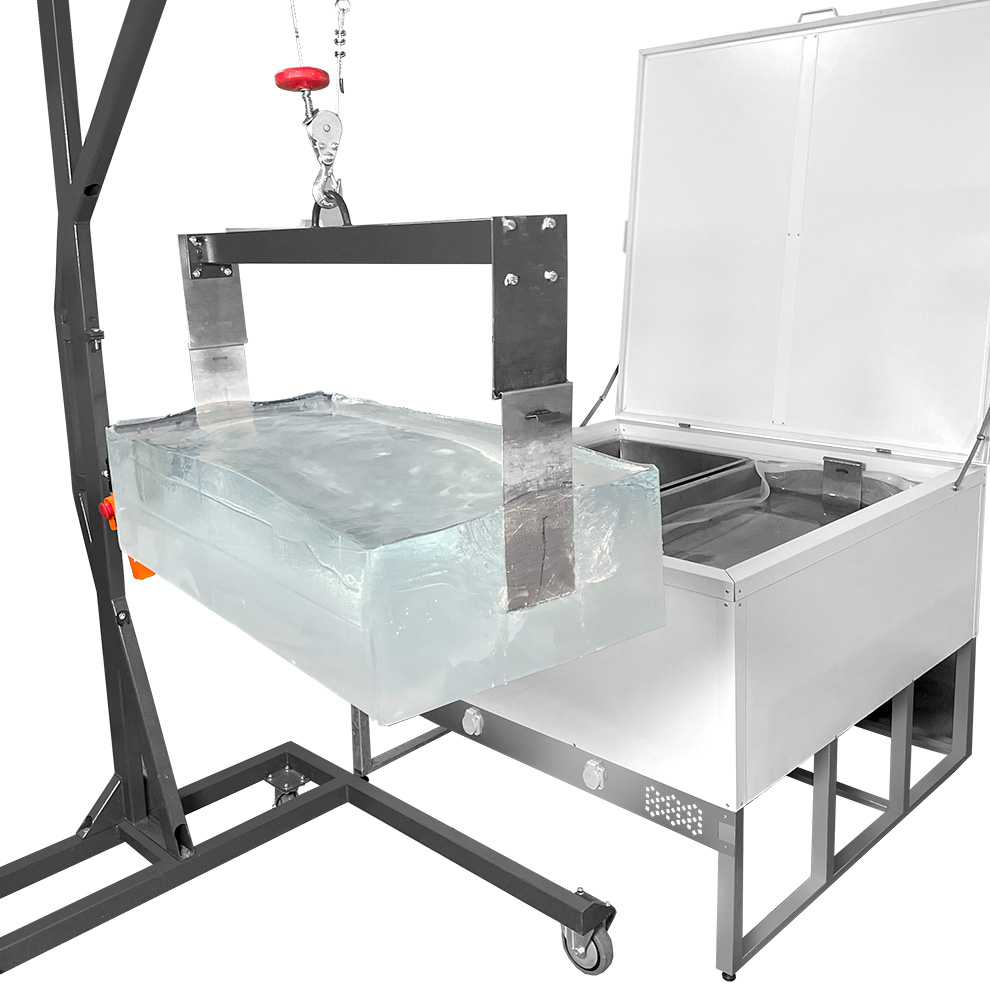

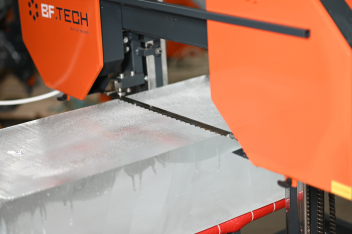

As you can see, some of the popular ice-carving techniques are time-consuming and require a lot of physical strength. Not all commercial business has the resour-ces to cut blocks of ice in such a manner. BF Tech delivers innovative solutions that optimize the whole ice-cutting process. Our years of experience in the ice industry prove that a bandsaw device is an ideal solution.

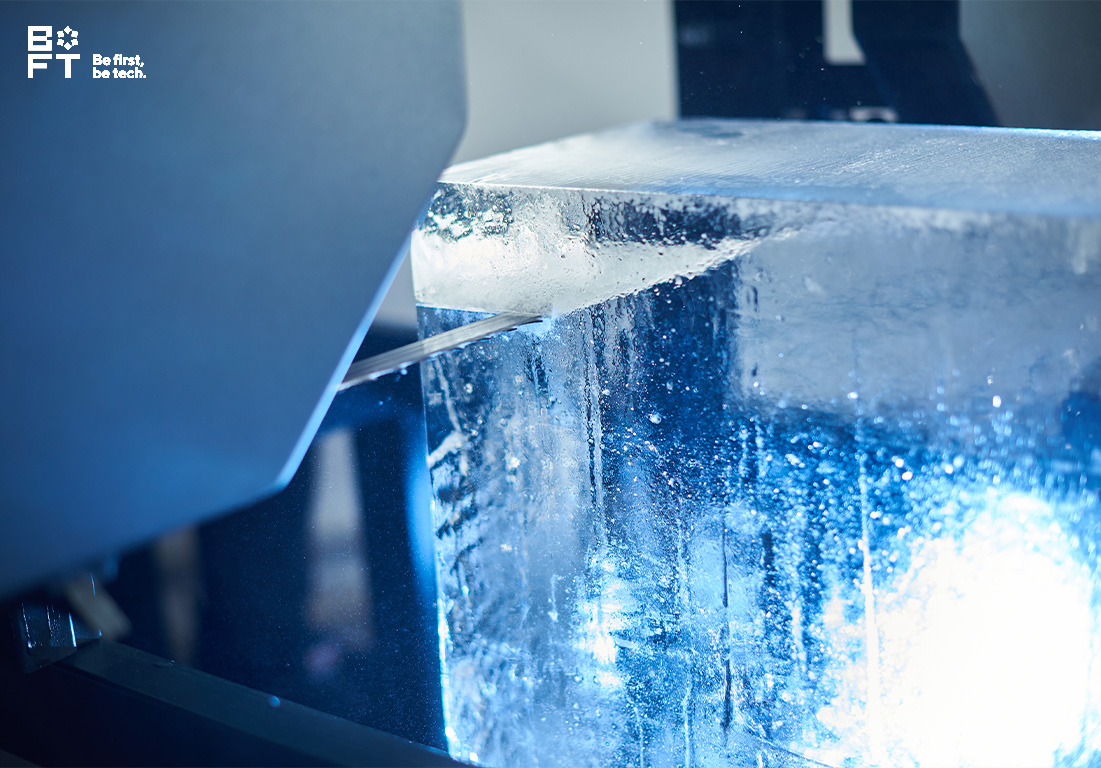

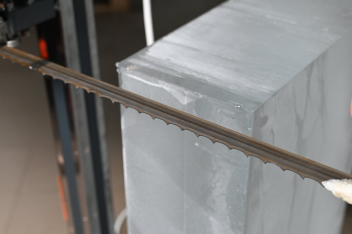

With Ice Band Saws, there will be no more struggles with how to cut block ice. Unlike other carving methods, bandsaws produce minimal waste and create precise cuts. The tool uses a continuous band of toothed metal to slice through

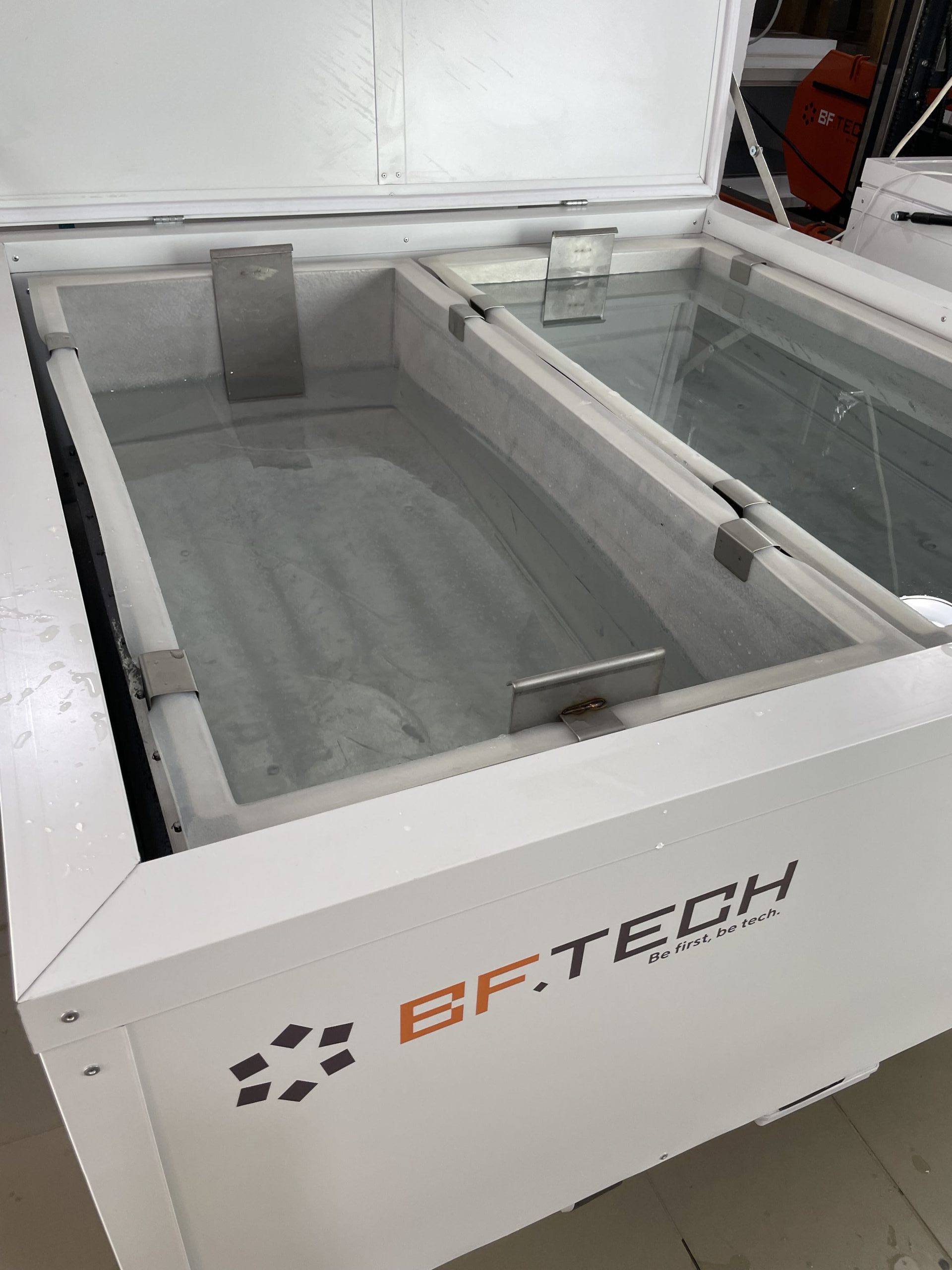

the ice. Our band-saws are designed to help the food and beverage services industry and other commercial businesses.

Using Ice Band Saw to cut block ice: Advantages and Features

What features make Ice Band Saws the best-voted method for ice-carving?

- Adjustable blade tension: BF Tech’s bandsaws allow operators to optimize blade performance for various ice types, letting them con-trol how to cut a block of ice to get the most precise results.

- Variable speed controls: You can manually adjust the speed of the blade to match the ice block density.

- Durable construction: BF Tech uses only high-quality materials and components to build the ice band saws to guarantee reliability and long-lasting service.

- Easy maintenance: Ice band saws are easy to clean and maintain, en-suring your ice-cutting process runs smoothly.

Ice Band Saw is an ultimate ice-cutting method with several benefits for commercial businesses. Here is why you should adopt the bandsaw method to deal with large ice blocks.

- Precision: The continuous blade makes sharp, uniform cuts through the ice, giving you a high-end result. Remember, ice quality can impact the customer service in your restaurant or bar.

- Minimal waste: Compared to all other carving methods, bandsaws produce minimal waste, helping you to use most of the ice block.

- Efficiency: Ice Band Saw can help rescue the time and labor resources required to slice the large blocks of ice, making them a go-to choice for commercial brands.

- Safety: Ice Band Saw is a safer solution than other carving techniques, such as chainsaws and chisels. With a bandsaw, you can reduce the risk of accidents and injuries for your employees at the workplace.

Ways BF TECH can help your business?

We worked in the industry for many years, providing commercial businesses world-wide with innovative and high-end solutions for ice makers and related equipment. At BF Tech, you will find great tool for cutting ice for an affordable price.

Our equipment is not just another appliance in your kitchen. It’s a solution to opti-mize your food and beverage business, elevate customer service, and take the workload off your employees. BF Tech sells specific tools to help you grow and reach your goals in the service industry.

We are committed to providing customers with luxury-quality products, technical support, and high-end solutions designed to help brands to thrive. Whether you’re looking for a specific tool or need advice to optimize your operations, reach out to our representative to let us help you.

FAQ

What industry uses the most ice blocks?

You can break a block of ice in several ways, including a hammer, mallet, ice pick, chisel, chainsaw, and bandsaw C70 . The best method depends on what results you’re expecting to get (a clean cut or crushed ice).

What is the difference between an ice cube and an ice block?

If you want to avoid messy cuts and ice cracking, you should use tools with sharp bandsaw blades like a handsaw or an ice band saw. Avoid using excessive force. Instead, work slowly and steadily to guarantee a precise and accurate cut.

Are ice machines expensive to run?

The most efficient ice tools are power tools such as a chainsaw, ice band saws, and ice crushers. These tools cut through ice quickly and easily with minimal effort, manual labor, and waste.